Why CNC Lathe Machining Is Essential for Precision Components

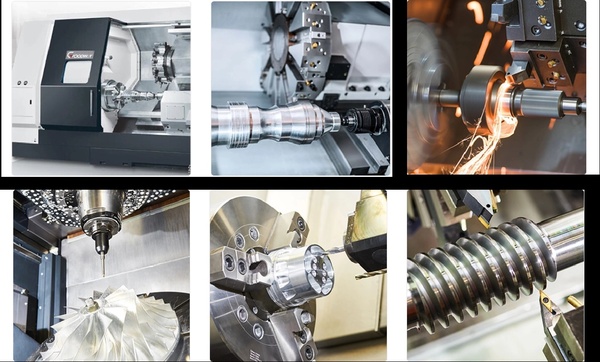

In modern manufacturing, CNC lathe machining plays a vital role in producing highly accurate, cylindrical, and rotational parts. These components are used across industries like aerospace, robotics, automotive, medical devices, and industrial machinery. With its ability to deliver tight tolerances, consistent repeatability, and high efficiency, CNC lathe machining helps businesses meet stringent performance and quality demands.

What Is CNC Lathe Machining?

The CNC lathe machining process involves mounting a workpiece on a rotating spindle while a computer-controlled cutting tool moves around it to remove material. This process is ideal for creating round or cylindrical shapes, such as shafts, bushings, threaded parts, and more. Unlike traditional manual lathes, CNC lathes automate the tool paths, allowing for more complex geometry, higher precision, and greater speed.

Modern CNC lathes often support multiple axes and can switch tools automatically, which increases versatility.

Key Advantages of CNC Lathe Machining

Precision & Consistency

One of the primary benefits of CNC lathe machining is its exceptional accuracy. CNC lathes can maintain tight tolerances and produce repeatable parts, significantly reducing human error. This precision is critical in industries where every micron counts.

High Efficiency & Automation

CNC lathes automate turning operations, reducing cycle times and enabling unattended or “lights-out” production. Automation also allows a single operator to oversee multiple machines, improving overall productivity.

Material Versatility

These machines are compatible with a variety of materials — from metals like aluminum and stainless steel to plastics. This flexibility makes CNC lathe machining ideal for many applications.

Cost-Effectiveness in Volume Production

While CNC lathes can cost more than manual lathes, their ability to precisely and efficiently produce large volumes helps offset the initial investment. Plus, reduced labor needs and minimal scrap further lower production costs.

Improved Safety

Because CNC lathes are automated, they isolate the operator from the cutting tool, reducing the risk of accidents.

Calculating CNC Lathe Machining Time

The CNC lathe machining time calculation is an important step when quoting or planning production. Key factors include:

-

Spindle speed (RPM)

-

Feed rate (distance the tool moves per revolution)

-

Depth of cut (how deep the tool cuts in each pass)

-

Tool change time and turret indexing

-

Setup, clamping, and part loading/unloading

Estimating with these parameters helps predict cycle time and cost more accurately. In high-volume production, small gains in efficiency can lead to significant savings.

Common Parts Made by CNC Lathe Machining

Typical CNC lathe machining parts include:

-

Shafts and axles

-

Bushings and collars

-

Threaded components (screws, bolts)

-

Spacers and standoffs

-

Custom turned components for assemblies

These parts often require precision turning, internal bores, thread cutting, and possibly secondary operations like drilling or milling.

CNC Lathe Machining Services: What to Look For

When you need CNC lathe machining services, here are some important considerations:

-

Machine Capability

Does the lathe center support the size, material, and tolerance you require? Multi-axis or sub-spindle lathes offer added flexibility. -

Quality Control

Reliable machinists use measurement tools (e.g., CMM, micrometers) to verify part dimensions and surface finish. -

Programming Expertise

Good CNC lathe services rely on experienced programmers who can optimize tool paths and minimize cycle time. -

Surface Finishing

After turning, many parts need finishing — polishing, plating, passivation, etc. A full-service facility will handle this in-house. -

Turnaround & Pricing

When choosing a service provider, review their lead times and how they estimate costs. Time calculation, setup, and production scale all influence final pricing. -

Local vs. Remote Services

For smaller runs or urgent needs, having CNC lathe machining near me can reduce logistics and accelerate delivery. For large volumes, international providers may offer cost benefits.

Why Choose XSTAR for CNC Lathe Machining

At XSTAR, we combine precision, efficiency, and expertise to provide top-tier CNC lathe machining services customized to your needs:

-

Advanced Equipment: Our factory features modern CNC lathes capable of turning aluminum, stainless steel, magnesium, ABS, acrylic, and more.

-

Expert Machining Process: We optimize the CNC lathe machining process — from programming, setup, turning, to secondary operations — for speed and accuracy.

-

Accurate Time Estimation: We use our experience to perform detailed lathe machining time calculation, ensuring you understand cycle times and costs.

-

Comprehensive Part Capability: Whether you need simple CNC lathe machining parts or more complex ones with internal geometry, we’ve got you covered.

-

Full-Service Machining: Beyond turning, we also handle milling, grinding, and polishing, plus post-treatment like anodizing, plating, and more.

-

Quality Assurance: We inspect every batch and part, using CMM and other tools to maintain tight tolerances and high repeatability.

-

Scalable Production: From prototypes to large runs, XSTAR can scale to your business needs with predictable costs and lead times.

-

Global & Local Support: Whether you are in the same city or overseas, XSTAR offers responsive service and shipping.

If you want high-quality, reliable CNC lathe machining, XSTAR is your trusted partner. Please contact us with your CAD drawings and specifications, and we’ll provide a clear quote and machining plan.

As an integrated manufacturing and trading company, we specialize in delivering CNC machining services, with a strong focus on CNC subcontracting and the precision processing of diverse metal components. Our production capabilities include

CNC aluminum machining,

CNC stainless steel machining,

CNC magnesium machining,

CNC acrylic machining,

CNC ABS machining, and

CNC plastic machining for a wide range of applications.

We also offer high-accuracy machining solutions for multiple industries, such as

robot parts machining,

aerospace component machining,

automotive parts machining,

medical parts machining,

as well as other industrial sectors requiring precise CNC-made components.

Our CNC services deliver outstanding precision, rapid processing speed, reliable quality, and strong material compatibility. A comprehensive list of finishing processes is available, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum coating, electroless plating, phosphating, passivation, silkscreen printing, and textured surface finishing.

We are a dedicated provider of cnc lathe machining, supplying both prototype and mass-production CNC solutions. If you are searching for a trustworthy cnc lathe machining manufacturer or need to request a cnc lathe machining price, feel free to get in touch with us anytime.