Understanding CNC Machine Milling Price and Equipment: A Guide by Xstar

Why Xstar Leads in CNC Machining Milling

When your project requires precision, flexibility and speed, the right machining partner matters. At Xstar, we specialise in cnc machining milling, blending advanced technology, streamlined processes and trusted service to deliver parts that perform — on time, on spec, and on budget.

Mastering CNC Machining Milling with Xstar

From the moment you upload a CAD file to the finished milled component, Xstar’s workflow is built around cnc machining milling. Our team assesses the geometry, material and finish requirements, selects the optimal machine — whether a 3-axis vertical mill or a full five-axis centre — and programmes the tool path. With our standardised process, we reduce variability and deliver consistent results. We believe that milling is not just cutting away material, but shaping performance into your part.

CNC Machine Milling and Turning: Integrated Solutions

Many parts today require not just flat surfaces or pockets but turned features, threaded bores or cylindrical interfaces. That’s why Xstar offers solutions combining cnc machine milling and turning. Utilizing turn-mill centres and advanced mill-turn machines, we seamlessly switch between milling and turning operations within one setup where possible, reducing part handling and improving accuracy.

CNC Machine Milling Price: Transparent & Competitive

When customers ask about cnc machine milling price, we deliver clear, itemised quotes. Our proprietary quoting engine considers machine time, tooling, material, finish and complexity. At Xstar we believe in transparent pricing: you see what you’re paying for — no hidden setup fees, no surprise hour-rates. This helps you plan budgets confidently and choose the milling service that suits your parts and scale.

CNC Machine Milling for Sale: What to Know

If you’re considering buying equipment, you’ll often search for cnc machine milling for sale. At Xstar we’ve invested in our own world-class equipment so you don’t have to. But understanding what makes a good purchase helps you evaluate our capabilities: look for bed size, axis count, spindle speed, tool-changer capacity, and rigidity. These factors influence what parts you can machine and how efficiently. We’re happy to explain our equipment specs so you know your parts are going to the right machine.

CNC Machine Milling Parts: Complexity Meets Precision

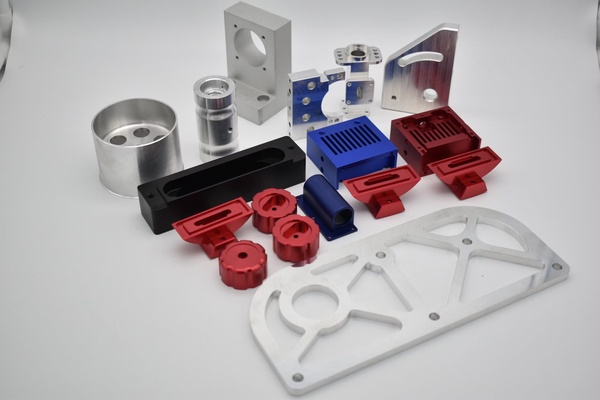

Our customers demand high-performance cnc machine milling parts, whether that’s structural brackets, aerospace housings, medical devices or complex consumer-electronics casings. At Xstar we program toolpaths for pocketing, contouring, drilling, tapping and finishing in one machine run. We advise on design for manufacturability (DFM) so you avoid costly trap features — for example avoiding deep pockets with no radius or walls thinner than the cutter diameter. (See typical guidelines on CNC milling design.)

5-Axis Milling Service: Tackling the Most Demanding Geometries

For parts with complex surfaces, undercuts or multiple orientations, Xstar offers full 5-axis Milling Service. Machines that handle five or more axes reduce setups, improve surface finish and accelerate production of sophisticated parts. As one industry article observes, such machines allow “more complicated forms or prevent the need to send the workpiece to another machine”.

Swiss Turning Services: A Complement to Milling

Many parts contain both milled and turned features. That’s why our complementary Swiss Turning Services are part of the Xstar offering. These high-precision lathes produce slender parts, turned detail features and fine tolerances that then feed seamlessly into our milling operations. The result: truly finished components ready for assembly, rather than separate milled and turned parts needing manual joinery.

Choosing Xstar for Your Milling Projects

Here’s why engineers choose Xstar for cnc machining milling:

-

Equipment breadth: from standard 3-axis mills to 5-axis centres and mill-turn combos.

-

Clarity on “cnc machine milling price” with itemised, fast quotes.

-

Full part consideration: milled surfaces, turned features, finishing, assembly readiness.

-

Ability to handle more than just flat features — our “cnc machine milling parts” include complex pockets, curved surfaces and precision finishing.

-

Seamless integration of milling and turning within one supply chain, thanks to combined milling & turning and Swiss turning services.

-

Quality focus, quick turnaround, DFM support and responsiveness.

Final Thoughts

In the modern manufacturing landscape, cnc machining milling is not just a commodity — it’s strategic. At Xstar, we’ve tailored our processes, machines and workforce to deliver parts that meet the full spectrum of expectations: precision, complexity, cost-control and time-to-market. Whether you need milled enclosures, turned-and-milled assemblies, or complex 5-axis geometries, our integrated offering ensures your part is made right — each time.

We are a professional manufacturing-and-trading integrated supplier specializing in CNC machining services, with extensive experience in contract CNC production and precision metal part fabrication. Our machining capabilities cover CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloys, CNC machining acrylic, CNC machining ABS, and CNC machining plastic materials of multiple categories.

We also support precision machining for various industries, providing high-quality parts for robotics machining, aerospace component machining, marine parts machining, automotive part machining, and medical component machining, meeting most industrial CNC precision requirements.

Our CNC machining solutions offer high accuracy, fast turnaround, stable quality, and excellent compatibility with different materials. A wide array of finishing processes is available, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, black oxide, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk-screen printing, and texture etching.

As a cnc machining milling manufacturer, we supply small-batch and large-scale CNC production services. For competitive cnc machining milling pricing or dependable cnc machining milling services, you are welcome to contact us anytime.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for handling.