Small Batch CNC Machining: A Practical Guide to Flexible, Precision Manufacturing

In today’s fast-changing manufacturing environment, small batch cnc machining has become an essential solution for companies that need flexibility, precision, and speed without committing to mass production. From early-stage product development to customized industrial components, small batch CNC machining allows manufacturers to produce limited quantities of high-quality parts while maintaining tight tolerances and cost control.

Unlike large-scale manufacturing, small batch cnc machining focuses on adaptability. It supports frequent design changes, rapid prototyping, and short production runs, making it ideal for startups, OEMs, and engineering teams seeking reliable results with minimal risk. In this guide, we explore how small batch CNC machining works, its benefits, service options in different regions, and the types of CNC machining centers that make it possible.

What Is Small Batch CNC Machining?

Small batch cnc machining refers to the production of a limited number of parts—typically ranging from a few pieces to several hundred—using computer numerical control (CNC) machines. The process uses digital designs (CAD/CAM) to guide milling, turning, or multi-axis machining operations with high precision and repeatability.

This approach bridges the gap between one-off prototypes and mass production. It offers the accuracy of full-scale CNC manufacturing while keeping tooling, setup, and inventory costs under control.

Why Small Batch CNC Machining Is in High Demand

Manufacturers increasingly choose small batch CNC machining for several key reasons:

-

Design flexibility: Easy to modify CAD files without expensive tooling changes

-

Fast turnaround: Shorter lead times compared to traditional production methods

-

High precision: Consistent tolerances even in low quantities

-

Lower financial risk: Reduced upfront investment

-

Scalability: Smooth transition from small batches to larger production runs

For companies working in aerospace, medical devices, electronics, and industrial automation, this balance of speed and accuracy is critical.

Core Capabilities and Applications

Small Batch CNC Machining Services

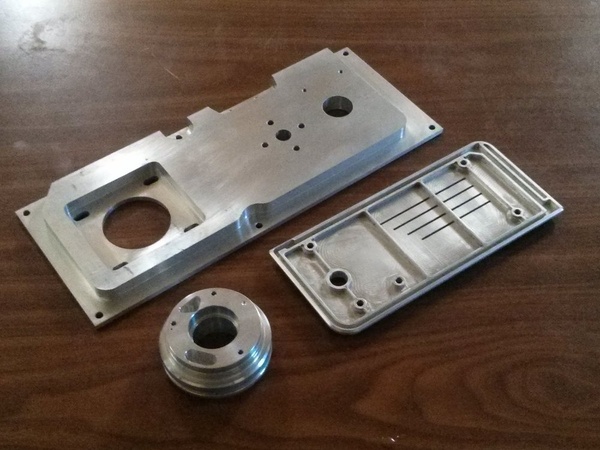

Professional small batch cnc machining services typically include CNC milling, CNC turning, and multi-axis machining, along with secondary processes such as drilling, tapping, and surface finishing.

These services are commonly used for:

-

Functional prototypes

-

Pilot production runs

-

Customized components

-

Replacement or legacy parts

-

Market testing before mass production

A reliable provider like Xstar offers integrated small batch CNC machining services that ensure consistent quality from the first part to the last.

Types of CNC Machining Centers

Understanding the types of cnc machining centers used in small batch production helps buyers choose the right manufacturing approach.

Common CNC Machining Centers:

-

3-Axis CNC Machining Centers

Ideal for simple to moderately complex parts with standard geometries. -

4-Axis CNC Machining Centers

Allow rotation around an additional axis, improving efficiency and accuracy. -

5-Axis CNC Machining Centers

Enable complex geometries, reduced setups, and superior surface finishes. -

CNC Turning Centers (Lathes)

Best for cylindrical or rotational parts such as shafts and bushings.

Small batch CNC machining often benefits from multi-axis machining centers because they reduce setup time and increase precision, especially for complex parts.

Regional Small Batch CNC Machining Options

Small Batch CNC Machining Near Me

Searching for small batch cnc machining near me is common for companies that value local support, faster communication, and reduced shipping time. Local suppliers often provide quick prototyping and easier collaboration during design iterations.

Benefits of local small batch CNC machining include:

-

Faster lead times

-

Easier quality inspections

-

Direct communication with engineers

-

Reduced logistics complexity

However, local availability and pricing may vary depending on region and capacity.

Small Batch CNC Machining Solutions in USA

Small batch cnc machining solutions in USA are known for strong engineering expertise, advanced equipment, and compliance with strict industry standards. U.S. suppliers are frequently chosen for aerospace, defense, and medical projects where regulatory compliance and documentation are critical.

Advantages include:

-

High machining accuracy

-

Strong quality systems

-

Intellectual property protection

-

Responsive technical support

While costs may be higher than offshore options, many companies choose U.S. solutions for critical or time-sensitive projects.

Small Batch CNC Machining UK

The small batch cnc machining UK market is well-established, serving automotive, aerospace, and industrial sectors. UK suppliers often emphasize precision engineering, tight tolerances, and consistent quality.

Key strengths include:

-

Advanced CNC technology

-

Skilled machinists and engineers

-

Experience with complex metal components

-

Strong export capabilities

UK-based small batch CNC machining is particularly attractive for European customers seeking regional production.

Materials Commonly Used in Small Batch CNC Machining

Small batch CNC machining supports a wide range of materials, depending on application needs:

-

Aluminum alloys: Lightweight, corrosion-resistant, cost-effective

-

Stainless steel: High strength and durability

-

Carbon steel: Economical and versatile

-

Brass: Excellent machinability

-

Engineering plastics: Lightweight and electrically insulating

Material choice directly impacts machining time, surface finish, and overall cost, making material selection a key part of the process.

Cost Considerations for Small Batch CNC Machining

While small batch CNC machining avoids expensive tooling, cost is still influenced by several factors:

-

Part geometry and tolerance requirements

-

Material type

-

Machine time and number of setups

-

Surface finishing processes

-

Order quantity

In many cases, optimizing part design for manufacturability can significantly reduce costs without compromising performance.

Quality Control in Small Batch CNC Machining

Quality assurance is especially important in small batch production, where each part represents a higher percentage of total output.

Professional suppliers typically implement:

-

Incoming material inspection

-

In-process checks

-

Final dimensional inspection

-

Measurement reports upon request

These practices ensure consistent results even in low-volume runs.

How to Choose the Right Small Batch CNC Machining Partner

When selecting a small batch CNC machining provider, consider:

-

Equipment capability – Access to appropriate CNC machining centers

-

Engineering support – DFM feedback and problem-solving

-

Material expertise – Experience with your required materials

-

Quality systems – Documented inspection and traceability

-

Scalability – Ability to support future production growth

Suppliers like Xstar focus on long-term partnerships, not just one-off orders.

Conclusion

Small batch cnc machining offers a powerful combination of precision, flexibility, and speed for modern manufacturing needs. Whether sourcing small batch cnc machining near me, evaluating small batch cnc machining solutions in USA, or exploring small batch cnc machining UK, understanding capabilities, materials, and machining centers helps ensure successful outcomes.

By leveraging the right small batch cnc machining services and choosing suitable types of cnc machining centers, manufacturers can reduce risk, accelerate development, and maintain high quality across limited production runs.

We are an integrated manufacturer providing CNC machining services, mainly focused on subcontract machining and the production of metal components. We specialize in small batch cnc machining and support CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloy, CNC machining acrylic, CNC machining ABS, and CNC machining plastic materials.

Our capabilities include robot machining, aerospace parts machining, automotive parts machining, and medical parts machining, covering most CNC precision parts required in industrial applications. Our CNC machining services deliver high precision, fast lead times, stable quality, and strong adaptability.

We also offer comprehensive surface finishing processes such as sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, black oxide, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk screening, and knurling. As a CNC machining service manufacturer, we provide batch and small batch cnc machining solutions. For product, manufacturer, and price related to small batch cnc machining, please contact us.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.