Custom Parts Manufacturing: Precision Solutions for Modern Industries

Custom Parts Manufacturing: A Complete Guide to Precision, Materials, and Industry Applications

In today’s highly competitive industrial environment, custom parts manufacturing has become a cornerstone of innovation, efficiency, and product differentiation. Companies across aerospace, automotive, medical, electronics, and industrial machinery rely on custom-made components to meet exact functional, dimensional, and performance requirements that standard off-the-shelf parts cannot satisfy.

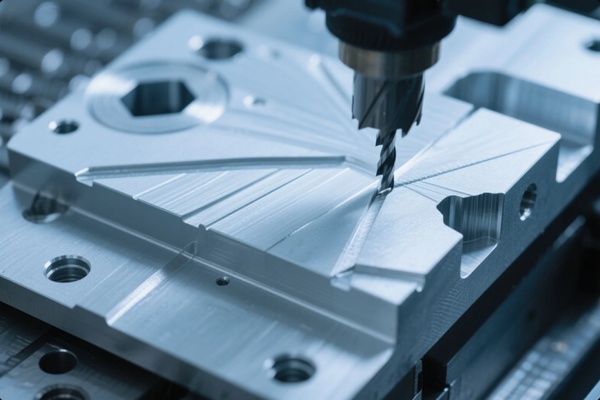

By leveraging advanced processes such as CNC machining, metal fabrication, plastic molding, and composite manufacturing, custom parts manufacturing enables businesses to transform unique design concepts into reliable, production-ready components. Manufacturers like Xstar provide end-to-end support—from engineering validation to full-scale production—ensuring precision, consistency, and scalability.

Custom Parts Manufacturing in Modern Industry

What Is Custom Parts Manufacturing?

Custom parts manufacturing refers to the production of components designed and built to specific customer requirements rather than standardized specifications. These parts are engineered for precise dimensions, materials, tolerances, and performance characteristics.

Unlike mass-produced items, custom parts manufacturing emphasizes flexibility, customization, and engineering collaboration. This approach allows manufacturers to optimize components for unique applications, improve product performance, and reduce long-term operational costs.

Key advantages include:

-

Exact fit and function

-

Enhanced product performance

-

Design freedom and innovation

-

Improved durability and reliability

-

Compatibility with complex assemblies

Custom Parts Fabrication: From Design to Reality

Custom parts fabrication focuses on shaping raw materials—such as metal sheets, bars, or tubes—into finished components using cutting, bending, welding, and machining processes. Fabrication is often the foundation of custom manufacturing projects, especially for structural or load-bearing parts.

In custom parts fabrication, engineers work closely with manufacturers to refine designs for manufacturability, ensuring optimal material usage and structural integrity. This collaborative approach shortens lead times and minimizes production risks.

Custom Metal Parts Manufacturing

Custom metal parts manufacturing is one of the most common forms of custom production. Metals such as aluminum, stainless steel, brass, copper, and titanium are widely used due to their strength, durability, and machinability.

Applications of custom metal parts manufacturing include:

-

Industrial machine components

-

Aerospace brackets and housings

-

Automotive structural and engine parts

-

Medical device frames

-

Energy and automation equipment

Advanced CNC machining, laser cutting, and precision finishing allow manufacturers like Xstar to achieve tight tolerances and excellent surface finishes in custom metal parts manufacturing.

CNC Custom Parts Manufacturing

CNC custom parts manufacturing uses computer numerical control systems to produce highly accurate and repeatable parts. CNC technology enables manufacturers to execute complex toolpaths and maintain consistency across production runs.

Benefits of CNC custom parts manufacturing include:

-

Micron-level precision

-

Excellent repeatability

-

Faster production cycles

-

Reduced human error

-

Efficient scaling from prototype to mass production

Because of these advantages, CNC custom parts manufacturing is widely used for high-performance applications that demand reliability and precision.

CNC Custom Parts Manufacturing LLC: Specialized Production Models

The term CNC custom parts manufacturing LLC commonly refers to specialized machining companies structured to provide focused, agile manufacturing services. These entities often support rapid prototyping, short-run production, and highly customized machining projects.

Such organizations prioritize flexibility, quick response times, and close engineering collaboration, making them ideal partners for startups, R&D teams, and niche industrial projects.

Custom Machine Parts Manufacturing

Custom machine parts manufacturing involves producing components designed specifically for mechanical systems, equipment, and assemblies. These parts often require strict tolerances and must integrate seamlessly into existing machinery.

Examples include:

-

Shafts, gears, and couplings

-

Precision housings and frames

-

Wear components and tooling

-

Automation and robotic system parts

Custom machine parts manufacturing helps extend equipment lifespan, improve operational efficiency, and support machinery upgrades or retrofits.

Custom Plastic Parts Manufacturing

Custom plastic parts manufacturing serves industries that require lightweight, corrosion-resistant, and electrically insulating components. Engineering plastics such as ABS, POM, Nylon, PEEK, and PTFE are commonly used.

Processes used in custom plastic parts manufacturing include:

-

CNC machining

-

Injection molding

-

Thermoforming

-

Vacuum forming

Plastic components are widely used in electronics, medical devices, consumer products, and industrial systems where weight reduction and chemical resistance are critical.

Custom Carbon Fiber Parts Manufacturing

Custom carbon fiber parts manufacturing supports high-performance industries that require exceptional strength-to-weight ratios. Carbon fiber composites are increasingly used in aerospace, motorsports, robotics, and advanced automotive applications.

Advantages of custom carbon fiber parts manufacturing include:

-

Extremely lightweight structures

-

High stiffness and strength

-

Excellent fatigue resistance

-

Advanced aesthetic finishes

Manufacturers like Xstar combine composite layup techniques with CNC trimming to ensure dimensional accuracy and repeatability.

Custom Car Parts Manufacturing

Custom car parts manufacturing plays a crucial role in automotive performance, restoration, and customization markets. These parts range from structural brackets to performance upgrades and aesthetic components.

Common applications include:

-

Engine and drivetrain components

-

Suspension and chassis parts

-

Interior and exterior accessories

-

Performance and racing components

Custom car parts manufacturing allows automotive engineers and enthusiasts to optimize vehicles for performance, safety, and unique design requirements.

Custom Manufacturing Companies: Choosing the Right Partner

Selecting the right custom manufacturing companies is essential for project success. A reliable partner offers not only production capability but also engineering expertise and quality assurance.

When evaluating custom manufacturing companies, consider:

-

Manufacturing technology and capacity

-

Material expertise

-

Quality certifications and inspection processes

-

Communication and project management

-

Scalability and long-term support

Leading companies like Xstar provide integrated solutions across metal, plastic, and composite manufacturing, ensuring consistency from prototype to production.

Industry Benefits of Custom Parts Manufacturing

The growing demand for custom parts manufacturing is driven by several key benefits:

-

Tailored solutions for unique applications

-

Improved product performance and reliability

-

Reduced assembly and maintenance costs

-

Faster innovation cycles

-

Competitive differentiation

As products become more complex, custom manufacturing continues to replace standardized components in high-value applications.

We are a CNC machining service provider integrating manufacturing and trading, mainly focused on OEM CNC machining and the production of various custom metal components. With strong capabilities in custom parts manufacturing, we deliver reliable machining solutions for diverse applications.

Our services cover CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloy, CNC machining acrylic, CNC machining ABS, and CNC machining plastics. These machining solutions are widely used for robot parts machining, aerospace parts machining, automotive parts machining, and medical parts machining, supporting most CNC precision parts required in marine and general industrial fields.

As a professional custom parts manufacturing factory, our CNC machining services feature high dimensional accuracy, fast production efficiency, consistent quality, and excellent process compatibility. To satisfy different technical and appearance requirements, we provide comprehensive post-processing options, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, spray painting, black oxide treatment, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk screening, knurling, and most common surface finishing processes.

We are a dedicated CNC machining service manufacturer offering batch CNC machining services. If you are searching for a dependable custom parts manufacturing partner or would like to inquire about CNC machining service pricing, please feel free to contact us.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.