Custom Metal Fabrication Services: How to Get Precision Metal Work by Xstar

Custom Metal Fabrication Services: Flexible, Reliable & Global Solutions by Xstar

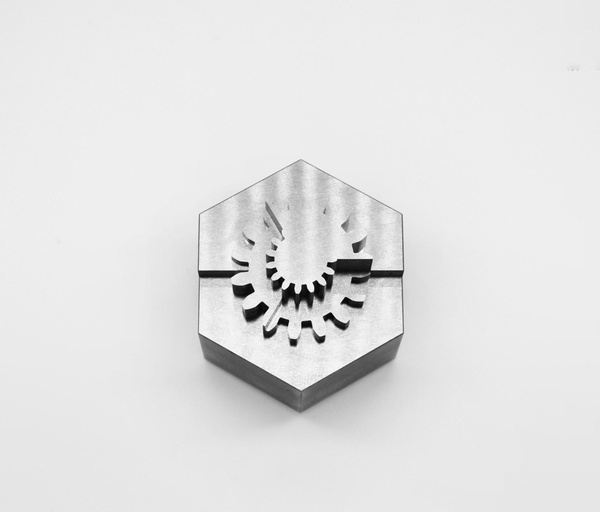

When off-the-shelf metal parts, enclosures or housings cannot satisfy your design or functional needs, custom metal fabrication services step in — offering flexibility, precision, and tailored solutions. At Xstar, we coordinate and deliver fabrication services, including sheet metal work, to meet diverse requirements — from prototypes to small-batch or full production, local orders to global supply.

What “custom metal fabrication services” means

Custom metal fabrication services refer to a suite of capabilities enabling a workshop or shop to take raw metal materials (sheet, plate, tube, bar, structural profiles) and process them — cutting, forming, bending, assembling or welding, machining (if needed), and finishing — into customized parts, housings, frames, enclosures, or assemblies per client specifications. When sheet metal is involved, these services are often described as sheet metal fabrication services.

This capability stands in contrast with standard mass-produced metal components, offering adaptability in design, material, geometry, finish and volume.

What sheet metal fabrication services offer

Providers specializing in sheet metal fabrication services — a key subset of custom metal fabrication — typically offer:

-

Sheet cutting & shaping: laser cutting, water-jet, shearing, shears, etc., to cut raw sheet to shape.

-

Bending, forming, folding: to create enclosures, brackets, panels, frames, ductwork, or complex geometry.

-

Punching / drilling / punching holes / cutouts: for ventilation, access panels, mounting points, connectors, cable entry, etc.

-

Welding / assembly / fastening: joining multiple sheet parts, reinforcing structures, attaching flanges or brackets.

-

Surface finishing & treatment: painting, powder-coating, plating, galvanizing, polishing, corrosion-resistant coatings — depending on application (indoor, outdoor, industrial, cosmetic).

-

Prototyping & small batch runs: Supporting single units, prototypes, or small-to-medium volume orders, giving flexibility for custom or evolving designs.

This versatility makes sheet metal fabrication services ideal for enclosures, control panels, HVAC ducts, equipment housings, structural frames, metal cabinetry, industrial guards, architectural metalwork, and more.

Custom metal fabrication services across global and local landscapes

Depending on your project’s scale, timeline, and location, there are multiple ways to access fabrication services:

-

Local fabrication: Searching sheet metal fabrication services near me can locate nearby workshops — valuable for quick prototyping, small orders, sample inspections, or projects needing on-site installation or measurement.

-

Regional or national suppliers: For larger orders or more demanding quality/finish/material requirements, broader suppliers in states/regions or countries may be used. Entities offering sheet metal fabrication services in USA or sheet metal fabrication services in India, for instance, provide expanded capacity, material sourcing options, and often competitive pricing for batch production.

-

Global outsourcing / offshore fabrication: In some cases, users consider sheet metal fabrication services in India or other countries to benefit from cost efficiencies, especially for larger volume orders or when shipping logistics are manageable.

-

Integrated custom fabrication services: For clients requiring both structural metalwork and detailed custom parts, full custom metal fabrication services — including sheet work, machining, welding, finishing — provide one-stop solutions, reducing complexity, communication overhead and ensuring consistent quality.

At Xstar, we help you choose the path that best aligns with your needs: whether local, regional, remote or global — we coordinate sourcing, fabrication, finishing and delivery.

Cost, quality and efficiency — what drives custom metal fabrication services

When selecting custom sheet metal fabrication services or broader metal fabrication services, some practical factors affect cost and suitability:

-

Material type and thickness: Sheet metal material (mild steel, stainless steel, aluminum, galvanized steel) and thickness influence cost, handling complexity, and finish requirements.

-

Complexity of geometry and features: More bends, cutouts, punched holes, welded assemblies, brackets, and custom features significantly increase labor time and cost.

-

Volume and batch size: Single-piece prototypes cost more per unit than small or medium batch runs due to setup overhead; but batch runs offer economies of scale.

-

Finishing and post-processing: Powder coating, painting, plating, galvanizing or other finishing add to cost but are often essential for durability, corrosion resistance or appearance.

-

Lead time and logistics: Rush orders, small batches, custom finish or tight tolerances may require more careful planning; global or outsourced fabrication may add shipping time or complicate logistics.

By partnering with a transparent and experienced service provider like Xstar, you gain clear quotes, material and process recommendations, quality control, and reliable lead times — helping balance cost, quality and delivery.

When to choose custom metal fabrication services

Custom metal fabrication services are particularly suitable when:

-

Your project requires unique metal parts that standard inventory cannot supply — custom housings, frames, enclosures, ductwork, structural parts.

-

You need a small batch or prototype — standard mass-production tooling is not cost-effective.

-

You require specific materials, coatings or finishes (e.g., stainless steel, powder-coated steel, galvanized components).

-

The design includes complex geometry, multiple parts, welded assemblies, custom cutouts, ventilation, mounting points, custom brackets or panels.

-

You want a one-stop solution — from raw material to finished part, reducing vendor management and possible mismatches.

How Xstar delivers custom metal fabrication services

At Xstar, our approach ensures quality, flexibility and customer satisfaction:

-

Requirement analysis & design consultation — we review your drawings/CAD files or concept, and advise on materials, tolerances, finish and cost.

-

Shop selection & procurement — depending on project scale and needs, we match you with suitable local, regional or global fabrication shops skilled in sheet metal work and metal fabrication services.

-

Fabrication & finishing — cutting, forming, welding/assembly, finishing, quality control and post-processing as needed.

-

Inspection, documentation & delivery — ensure dimensional accuracy, structural integrity, surface finish, packaging and delivery.

-

Support & iteration — for prototypes or evolving designs, we help manage revisions, re-runs, small-batch productions, or scaling up as needed.

Whether you need a custom metal frame, enclosure, equipment housing, industrial panel, or custom sheet metal parts — Xstar handles it end-to-end.

As a manufacturing-and-trading integrated company specializing in CNC machining services, we focus on contract CNC manufacturing and the precision machining of various metal components. Our capabilities cover a wide range of materials, including

CNC machining aluminum profiles,

CNC machining stainless steel,

CNC machining magnesium alloy,

CNC machining acrylic,

CNC machining ABS, and

CNC machining plastic materials.

We also support advanced processing needs such as

robot machining,

aerospace component machining,

automotive parts machining, and

medical component machining,

covering most precision CNC parts required across industrial sectors.

Our CNC machining services deliver high accuracy, fast turnaround, stable quality, and strong compatibility with diverse applications. Post-processing options include sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, electroless plating, phosphating, passivation, silk printing, and texture etching.

As a dedicated CNC machining supplier, we offer large-volume CNC production services. For inquiries about CNC machining service pricing, feel free to contact us.

To better support browsing, we also provide direct access related to

product, manufacturer, and price information for

custom metal fabrication services product,

custom metal fabrication services manufacturer,

and custom metal fabrication services price.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.