Complete Guide to CNC Machining Price and Online Quote Evaluation

Understanding CNC Machining Price: What Affects Cost and How to Optimize It

CNC machining price is one of the most important considerations for companies sourcing precision components across automotive, aerospace, robotics, consumer electronics, and industrial sectors. Whether you are ordering prototypes, low-volume batches, or large-scale production, understanding how CNC machining price is calculated can help you control cost while ensuring part quality. Many companies today also look for oem cnc machining parts, cnc machining online quote platforms, and cnc machining custom parts to meet flexible manufacturing needs. As global competition increases, more buyers are also comparing oem cnc machine manufacturers to evaluate scalability and long-term production cost.

In this article, we break down the major factors that influence CNC machining price, compare materials, discuss industry-specific tolerances, and explain how buyers can reduce cost without sacrificing performance.

Key Factors That Shape CNC Machining Price

CNC machining price depends on several core elements: material type, part geometry, tolerances, quantity, machining time, and secondary processes. Understanding these factors allows buyers to make better design decisions and improve cost efficiency.

Material Selection and Its Influence on CNC Machining Price

Material plays a major role in cnc machining price. Softer materials such as aluminum or plastic are faster to cut and generate lower tool wear, which reduces machining time and cost. In contrast, stainless steel, titanium, or hardened tool steel require slower cutting speeds and specialized tooling, increasing overall cnc machining price.

For companies requiring oem cnc machining parts, material choice becomes especially important because mass production magnifies even small differences in cycle time or scrap rate. Choosing the right grade—without unnecessary hardness—can drastically optimize cost.

Complexity and Geometry of CNC Machining Custom Parts

The complexity of cnc machining custom parts directly affects machining time. Parts with deep cavities, thin walls, micro-features, multi-axis surfaces, or tight tolerances need additional tool changes and complex toolpaths, increasing cnc machining price.

Designers can also use cnc machining online quote platforms to estimate the impact of each design change on the final cost. Uploading the CAD file helps engineers identify unnecessary features and propose optimizations for a lower cnc machining price.

Comparing CNC Machining Price Across Different Materials

CNC Machining Price for Aluminum Parts

Aluminum is known as the most cost-efficient material for CNC machining due to its excellent machinability. This results in reduced lead time and a significantly lower cnc machining price. Many oem cnc machine manufacturers rely on aluminum for prototype parts, housings, brackets, and heat-dissipation components.

CNC Machining Price for Stainless Steel Parts

Stainless steel is harder and stronger, which leads to longer machining cycles and a higher cnc machining price. Its corrosion resistance and strength make it necessary for industries such as marine, medical, and heavy industrial applications.

CNC Machining Price for Brass and Copper

Copper and brass offer excellent conductivity and are commonly used in electrical and precision instruments. Their machinability is high, but the raw material cost is also higher, influencing overall cnc machining price.

CNC Machining Price for Plastics

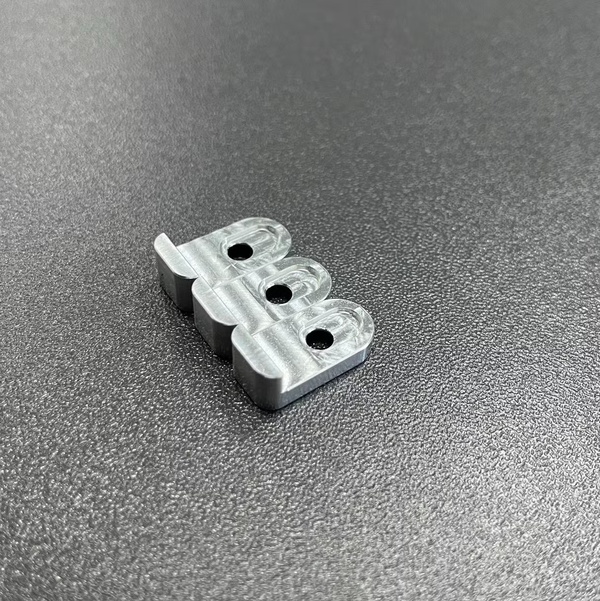

Plastics such as ABS, POM, and PC are generally easier and faster to machine, offering the lowest cnc machining price. For many consumer electronics companies ordering cnc machining custom parts, plastic provides cost-effective prototyping and functional testing at scale.

CNC Machining Price by Industry: Technical Requirements and Cost Differences

Automotive Industry Requirements

Automotive components often require precise dimensions and repeatability. While tolerances are not always extremely tight, large batch quantities significantly lower the cnc machining price per part. When sourcing oem cnc machining parts, automotive companies prioritize stability, long-term supply, and testing capabilities.

Aerospace and Defense Components

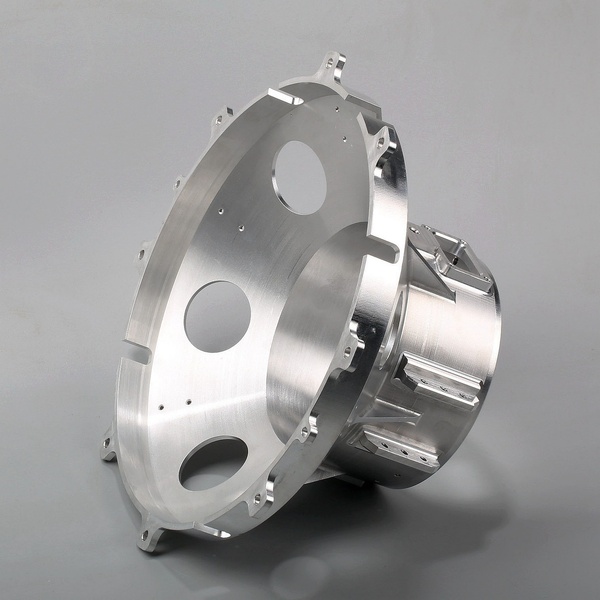

Aerospace parts often require highly specialized materials and extremely tight tolerances. Because machining titanium and high-strength alloys takes more time, cnc machining price is much higher in this sector. Many aerospace suppliers work closely with oem cnc machine manufacturers to ensure compliance with strict certification standards.

Robotics and Automation Components

Robotics involves many cnc machining custom parts such as gears, brackets, joints, shafts, and housings. The complexity of multi-axis surfaces increases cnc machining price but allows precise function and long-term reliability.

Medical Device Manufacturing

Medical parts require high-grade stainless steel or titanium, mirror polishing, and strict quality control. This results in a higher cnc machining price compared with standard industrial components.

How CNC Machining Online Quote Systems Impact Price Transparency

Modern cnc machining online quote systems allow customers to upload 3D models and instantly calculate machining time, material cost, and post-processing cost. This transparency helps buyers make faster decisions, compare suppliers, and optimize cnc machining price by adjusting part design or tolerances.

These tools are especially beneficial for startups or engineers who require fast prototypes or oem cnc machining parts without long waiting cycles.

Working With OEM CNC Machine Manufacturers to Reduce Cost

Partnering with reliable oem cnc machine manufacturers provides several advantages:

-

Better process optimization reduces cnc machining price for large batches

-

Access to multi-axis machining centers increases precision and reduces rework

-

Professional engineering teams help modify designs to lower machining time

-

Integrated surface finishing minimizes outsourcing cost

-

Economies of scale significantly reduce long-term pricing

Quality OEMs also ensure stable supply, consistent accuracy, and rapid turnaround—especially important for companies requiring ongoing cnc machining custom parts.

How XSTAR Helps You Optimize CNC Machining Price

At XSTAR, we specialize in CNC machining services covering aluminum, stainless steel, brass, magnesium, acrylic, ABS, and various plastic materials. With advanced equipment, skilled engineers, and complete post-processing capabilities, we offer competitive cnc machining price without compromising precision or quality.

Whether you need oem cnc machining parts, batch production, prototypes, or long-term custom manufacturing, we can provide reliable and cost-effective solutions. Contact us anytime for accurate cnc machining online quote support and professional engineering guidance.

We are a manufacturing and trading company specializing in CNC machining services, focusing mainly on CNC subcontracting and precision machining of various metal components. Our capabilities cover a wide range of materials, including CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloy, CNC machining acrylic, CNC machining ABS, and CNC machining plastic materials. We provide high-accuracy machining solutions for multiple industries such as robotics machining, aerospace component manufacturing, marine parts production, automotive parts machining, medical component machining, and other industrial applications requiring complex CNC precision parts.

Our CNC machining service ensures tight tolerances, fast turnaround, stable quality, and excellent compatibility. Post-processing options include sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, chemical plating, phosphating, passivation, silk printing, texture etching, and many other finishing processes.

As a professional CNC machining manufacturer, we provide both small-batch and large-scale production. For inquiries about product-related cnc machining price, manufacturer-related cnc machining price, or service-cost cnc machining price, feel free to contact us anytime.

Portions of this article are sourced from the internet. Should any inaccuracies be found, please contact us for resolution.