CNC Machining Aluminum: Mastering the Art of Precision Aluminum Manufacturing

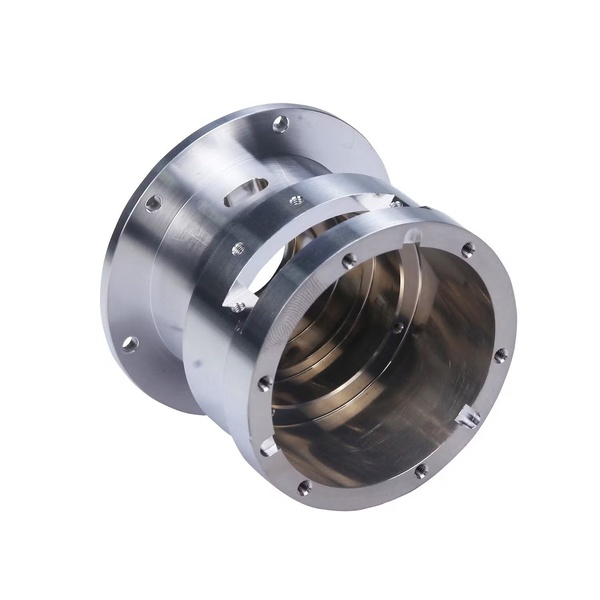

In today’s high-speed manufacturing world, cnc machining aluminum has emerged as a leading process for producing lightweight, high-performance parts with excellent machinability. For companies like Xstar, specializing in custom aluminum components, CNC machining aluminum is not just a service—it is a strategic advantage. Whether you’re designing parts for aerospace, automotive, consumer electronics or architectural applications, understanding how to leverage cnc machining aluminum will give you a competitive edge.

Design and Material Selection for CNC Machining Aluminum

When embarking on a project with cnc machining aluminum, the first step is choosing the right material and defining part geometry. Aluminum is known for its high strength-to-weight ratio, natural corrosion resistance, and ease of machining. Aluminum alloys machine three to four times faster than steel, giving a clear benefit in production speed and cost.

In this phase you will often decide to incorporate elements such as cnc machine aluminum profile into your design—extruded shapes, frames, structural rails—that are specifically configured for CNC machining aluminum. You might also consider cnc machine aluminum composite panel applications when outer skins and sandwich-core structures are required. Choosing the right profile or composite panel determines not only material cost but also how readily CNC tools can engage the material.

Material Grades & Their Impact

Selecting the correct grade of aluminum affects manufacturability. For instance, the 6xxx series (like 6061) is highly popular for cnc machining aluminum due to its balance of strength, corrosion resistance and machinability. The 7xxx series (such as 7075) offers higher strength but more challenging processing.

When you combine material grade selection with design, you create parts optimized for CNC processing. For example, an aluminum block intended for an aluminum block cnc machine operation needs to have features such as proper fillets, accessible tool paths, and minimal thin-wall sections to avoid deformation.

Understanding Cost: CNC Machine Aluminum Price

One of the most frequent questions that come from clients is: “What will the cnc machine aluminum price be for my part?” To answer this, you must consider multiple factors: material cost, machining time (which is influenced by geometry and tolerance), tooling wear (affected by certain aluminum alloys and operations), surface finish requirements, and post-processing (such as anodizing or powder coating).

Because aluminum is easier to machine than many metals, the cnc machining aluminum cost often comes in lower than alternatives like stainless steel or titanium. However, if your design includes an aluminum block cnc machine setup with a large block of 7075 alloy, tight tolerances, and complex multi-axis milling, the cnc machine aluminum price will rise significantly. At Xstar, we offer transparent costing models for cnc machining aluminum parts that help customers understand how design decisions impact cost.

CNC Milling Aluminum: Practical Considerations

When you specify a project for cnc machining aluminum, one of the core processes is milling. cnc milling aluminum remains the most common technique to shape aluminum blocks, plates or profiles. Milling enables removal of material, creation of pockets, slots, contours, and surfaces.

CNC Milling Aluminum Feeds and Speeds

Optimization of cnc milling aluminum feeds and speeds is vital. For example, typical roughing and finishing ranges vary by tool and machine; setting proper feeds and speeds ensures efficient material removal, extended tool life and excellent surface finish when performing cnc machining aluminum. Using a correct tool geometry (sharp carbide, 2- or 3-flute end mills) and adequate chip evacuation are part of best practice.

Design for Milling Success

To support effective cnc milling aluminum, avoid extremely thin walls (which can deflect), reduce internal sharp corners, provide fillets and make sure tool accessibility is good. These design for manufacturability (DFM) strategies help keep the cnc machine aluminum process predictable and cost-effective.

CNC Cutting Aluminum Sheet & Composite Panels

Beyond blocks and profiles, many applications leverage sheet and panel materials. When you deal with cnc cutting aluminum sheet, you are removing material from thin aluminum plate or sheet stock—commonly used in enclosures, housings or architectural panels. CNC machining aluminum in sheet form enables lightweight, intricate designs.

In parallel, cnc machine aluminum composite panel systems (which are aluminum-metal with a core, such as aluminum-plastic-aluminum) are used in architectural cladding or signage. The cnc machining aluminum process for composite panels must account for sandwich construction, potential delamination, different core materials, and tool path strategies to maintain edge quality.

Cut-paths, feed rates, tool selection and edge finishing are key when performing cnc cutting aluminum sheet or composite panel. Proper planning prevents edge burn, burring or distortion.

CNC Machine Aluminum Profile & Structural Parts

Structural shapes like extruded aluminum rails or fins are often processed via cnc machine aluminum profile operations. For example, a machine shop may take an extruded profile and perform cnc machining aluminum operations—milling slots, drilling holes, tapping threads—to create a finished structural bracket or heat-sink.

Because profiles often have regular geometry, tool paths can be efficient, equipment set-up minimal, and lead times fast. This makes them an excellent option for scalability. When you quote your part, review whether starting from a profile versus starting from a solid block will reduce the cnc machine aluminum price.

CNC Aluminum Machining Service: End-to-End Capabilities

When you source parts, you’re looking for a reliable cnc aluminum machining service provider — Xstar stands out as an example of a full-service partner. A reputable provider handles material procurement, CNC machining aluminum, finishing (anodizing, powder coating), inspection, packaging and logistics.

Working with a machining partner familiar with aluminum ensures the best practices are used from design to delivery. That includes selecting proper aluminum grades, verifying tool parameters, optimizing setup, controlling chips, and maintaining tight tolerances. The result: high-quality parts delivered on time and within budget.

Managing Challenges in CNC Machining Aluminum

While aluminum offers many advantages, it also presents challenges when processed via cnc machining aluminum. These include:

-

Chip adhesion / built-up edge: Soft aluminum chips tend to stick to tools, affecting accuracy and finish.

-

Thin-wall deflection / vibration: Thin features may deflect under machining forces, leading to poor tolerances.

-

Thermal expansion: Aluminum’s high thermal conductivity means heat can cause dimensional drift during machining.

-

Tool wear due to alloying elements: Some aluminum alloys contain silicon, which can accelerate tool wear.

By careful planning, proper tool choice, cooling strategies, and clamping/support design, a good cnc machining aluminum workflow can minimize these issues.

Applications and Future Trends

Thanks to its strong performance characteristics, cnc machining aluminum finds application in aerospace components, automotive frames, consumer electronics housings, architectural panels, medical devices and more. As industries demand lighter, stronger and more sustainable parts, the importance of cnc machining aluminum grows.

Manufacturers like Xstar leverage advanced 5-axis capabilities, high-speed milling, and automated finishing to deliver parts that meet modern requirements. The recyclability and cost-effectiveness of aluminum make the process highly sustainable and future-friendly.

Conclusion

Whether you are planning to use cnc machining aluminum parts for high-performance equipment, or you’re evaluating cnc machine aluminum price, exploring cnc machine aluminum profile or cnc machine aluminum composite panel, or engaging an expert cnc aluminum machining service, understanding the fundamentals of CNC machining aluminum is critical. By mastering cnc milling aluminum, cnc cutting aluminum sheet, and optimizing cnc milling aluminum feeds and speeds, you position your project for success. Partnering with a knowledgeable provider like Xstar ensures that your components deliver both performance and value.

We are an integrated manufacturing and trading company specializing in cnc machining aluminum services. Our main focus is contract CNC machining and precision production of a wide variety of metal parts. We provide expert machining for aluminum CNC machining, stainless steel CNC machining, magnesium alloy CNC machining, acrylic CNC machining, ABS CNC machining, and plastic CNC machining, covering both metal and plastic raw materials.

Our CNC capabilities support multiple industries, delivering high-precision components for robot parts machining, aerospace parts machining, marine parts machining, automotive parts machining, medical parts machining, and general industrial applications. Our services ensure high accuracy, fast turnaround, stable quality, and excellent material compatibility.

We also offer a wide range of surface finishing processes, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, chemical plating, phosphating, passivation, silk printing, and textured finishing.

As a professional cnc machining aluminum manufacturer, we provide scalable batch CNC machining solutions. For more details on cnc machining aluminum, manufacturer information, or cnc machining aluminum pricing, please contact us.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.