Affordable Aerospace CNC Machining Parts – XSTAR Manufacturer with Certified Quality

Why Aerospace CNC Machining Is a Critical Capability

In today’s aerospace industry, aerospace CNC machining is more than just a manufacturing method — it’s essential for producing high-precision, reliable, and lightweight components. Aerospace applications demand tolerance, repeatability, and material performance that only advanced CNC machining can deliver. Whether for aircraft, spacecraft, or high-performance drones, every part must meet rigorous standards for safety and performance.

Before we begin, if you need a CNC machining service quote, please contact us for a free estimate.

What Is Aerospace CNC Machining?

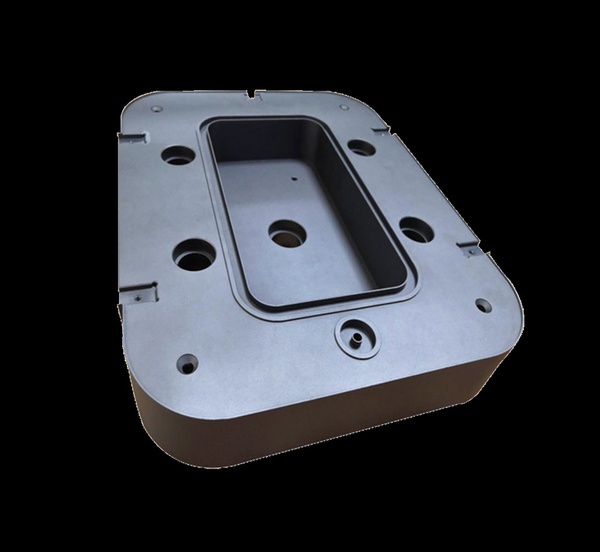

Aerospace CNC machining refers to computer numerical control (CNC) manufacturing tailored for aerospace parts. In this process, digital models are converted into precise toolpaths, and CNC machines—often 5-axis—cut, mill, turn, or grind raw materials like aluminum or stainless steel to exacting specifications. These parts serve critical roles such as structural brackets, landing gear components, fuel systems, and electrical housings.

Because of the extreme demands in aerospace, machining often requires micron-level tolerances.Modern CNC machining systems also pair with rigorous inspection and documentation to ensure traceability and compliance.

Key Benefits of Aerospace CNC Machining

Precision & Tight Tolerances

Aerospace CNC machining supports very tight tolerances — sometimes measured in microns — which is critical for mission-critical components.

Lightweight & High-Strength Materials

A key advantage is the ability to machine lightweight, high-performance materials. Aluminum alloys, titanium, and advanced stainless steels are commonly used in aerospace to minimize weight without sacrificing strength.

Complex Geometries & Multi-Axis Capability

With 5-axis CNC machines, aerospace parts with highly complex shapes — like turbine blades, structural frames, or wing components — can be machined in a single setup.This reduces setup time, lowers risk, and accelerates production.

Consistency & Repeatability

CNC machining ensures each batch or prototype part is manufactured consistently. Because the process is automated, human error is minimized, and parts can be reproduced reliably.

Efficient Material Use & Low Waste

Optimized tool paths and advanced programming reduce material waste, a crucial factor when working with expensive aerospace-grade metals.

High-Quality Surface Finishes

Post-machining, aerospace parts can receive high-end surface treatments such as hard anodizing, passivation, or polishing to improve durability, reduce corrosion, and meet performance requirements.

Traceability & Quality Control

Due to strict safety and regulatory requirements, aerospace CNC machining often includes full traceability, documentation, and inspection (e.g., CMM measurement) to ensure part integrity.

Challenges & Considerations in Aerospace CNC Machining

-

Material Complexity: Machining aerospace-grade materials (like titanium or high-strength alloys) can be difficult due to hardness, thermal behavior, or brittleness.

-

Certifications & Standards: Suppliers often need to maintain certifications like AS9100 or ISO 9001, plus strict process documentation to comply with aerospace requirements.

-

High Cost: Because of advanced machines, tight tolerances, and premium materials, aerospace CNC machining price can be significantly higher than for general machining.

-

Complex Programming & Setup: Multi-axis machines and complex parts require skilled programmers, CAD/CAM engineers, and rigorous fixture work.

Common Aerospace CNC Machining Parts

Some typical aerospace CNC machining parts include:

-

Structural brackets and frames

-

Landing gear components

-

Fuel system manifolds and housings

-

Electrical connector housings

-

Valve bodies and hydraulic parts

-

Engine or turbine-related components

These parts often require multiple operations — milling, turning, drilling — and tight tolerances to function safely in flight.

How CNC Machining Firms Manufacture Aerospace Parts

-

Design & Simulation

Engineers start by designing the part in CAD, then use CAM software to plan toolpaths. Simulations help verify that the part geometry is machinable, and that tool changes, cutting forces, and tolerances are optimized. -

Multi-Axis Machining

Aerospace shops often use 5-axis CNC machining for its ability to handle complex geometries in minimal setups. -

Rough Machining → Finishing

The process may begin with roughing (fast material removal) and end with finishing passes that bring the part to final tolerance and surface quality. -

Inspection & Quality Assurance

After machining, parts are inspected using CMMs or other metrology tools to ensure dimensional accuracy. Full documentation and traceability are created for every batch. -

Post-Processing

Surface treatments like anodizing, passivation, polishing, or others are applied to meet functional, durability, or corrosion-resistance requirements.

Estimating Aerospace CNC Machining Price

The aerospace CNC machining price depends on factors such as:

-

Material type (e.g., aluminum vs titanium)

-

Part complexity and number of operations

-

Precision and tolerance requirements

-

Batch size (prototype vs production)

-

Post-processing (surface treatment, inspection)

-

Certifications or traceability needs

Because of these variables, quoting often requires detailed CAD files and engineering dialogue. But due to careful process optimization and experienced machining partners, cost-efficiency can still be achieved without compromising quality.

Why Choose XSTAR for Your Aerospace CNC Machining Needs

At XSTAR, we are a vertically integrated CNC machining manufacturer that specializes in aerospace CNC machining. Here’s why aerospace companies choose us:

-

We machine a wide range of materials — aluminum alloys, high-grade stainless steel, magnesium, plastics — to meet rigorous aerospace standards.

-

Our capabilities include precision milling, turning, grinding, and multi-axis machining to handle complex aerospace geometries.

-

We offer comprehensive post-processing: anodizing, polishing, passivation, plating, and more, to deliver parts that are ready for high-stress aerospace environments.

-

We enforce rigorous quality control and traceability, backed by inspection systems and documentation.

-

With our efficient, well-optimized workflow, we deliver competitive aerospace CNC machining prices while maintaining high production quality and consistency.

If you need high-precision aerospace CNC machining parts, or want a reliable aerospace CNC machining parts manufacturer, XSTAR is ready to work with you. Contact us with your drawings and specifications — we’ll offer you a clear quote and a robust plan to manufacture your aerospace components.

We are an integrated trading and manufacturing company specializing in CNC machining services, mainly focused on CNC subcontracting and precision CNC machining of various metal parts. Our machining capabilities include CNC machining of aluminum profiles, CNC machining of stainless steel, CNC machining of magnesium alloys, CNC machining of acrylic, CNC machining of ABS, and CNC machining of various plastic materials. We provide precision CNC machining for a wide range of industries, including robotics machining, aerospace component machining, marine component machining, automotive parts machining, medical devices, industrial equipment, and many other fields requiring high-accuracy CNC parts.

Our CNC machining services offer high precision, fast processing efficiency, stable quality, and strong compatibility. We support an extensive list of surface finishing options such as sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, electroless plating, phosphating, passivation, silkscreen printing, and texture finishing.

As a professional CNC machining service manufacturer, we provide batch CNC machining services. For inquiries about CNC machining service pricing, feel free to contact us. We also support internal linking for aerospace cnc machining, aerospace cnc machining manufacturer, and aerospace cnc machining price to help enhance navigation across related product pages on the website.

Certain text or images in this article are sourced from the internet. Should any issues arise, please contact us for resolution.