Titanium CNC Parts: Precision Machining, Costs & Custom Solutions Explained

Titanium CNC Parts: Ultimate Guide to Precision, Cost, and Custom Solutions

In today’s advanced manufacturing landscape, titanium cnc parts have become a cornerstone of high-performance industries — from aerospace and medical to automotive and defense. These components deliver an exceptional strength-to-weight ratio, superior corrosion resistance, and durability that few other metals can match. Whether sourced as Wholesale titanium alloy CNC parts or bespoke designs from an expert Titanium alloy CNC parts manufacturer, titanium remains a premium choice for precision engineering projects.

What Makes Titanium CNC Parts Special?

Titanium, especially high-grade alloys such as Ti-6Al-4V (also known as Grade 5), combines remarkable mechanical properties with lightweight performance. This makes titanium alloy CNC parts ideal for applications where strength, corrosion resistance, and weight reduction are critical. The machining process uses computer numerical control (CNC) technology that precisely cuts and shapes titanium alloy billets into finished components.

The material’s corrosion resistance means parts withstand harsh environments, while the strength-to-weight ratio enables designs that perform reliably under stress without adding unnecessary bulk — a key factor in aerospace and medical uses.

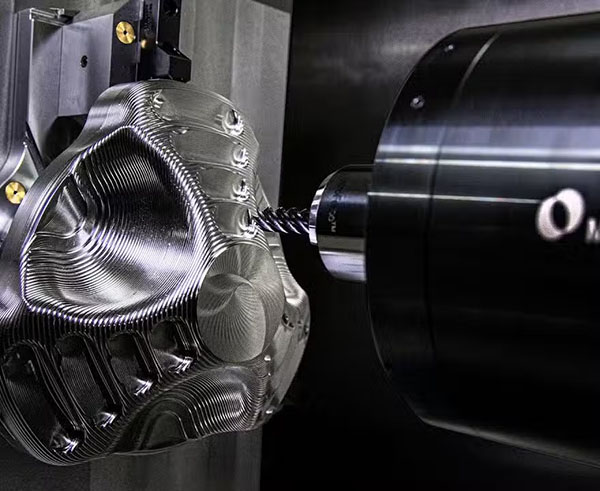

Titanium Alloy CNC Parts Machining: Precision at Its Best

When you engage in Titanium alloy CNC parts machining, cutting-edge CNC mills and lathes are used to remove material based on precise CAD models. Advanced 3-, 4-, or even 5-axis machines produce complex geometries with tight tolerances — often down to ±0.01 mm for critical parts.

At the heart of the machining process:

-

CNC Milling: Rotating cutters remove material to create slots, holes, pockets, and surfaces.

-

CNC Turning: A rotating workpiece allows cutting tools to create symmetric shapes like shafts or rings.

-

Finishing: Surface treatments — such as bead blasting, polishing, or anodizing — improve appearance and functionality.

Compared to other manufacturing methods, CNC machining delivers exceptional repeatability and precision, making it ideal for both prototype runs and full production batches.

Choosing Between Custom and Standard Solutions

One major advantage in the titanium parts market is the availability of Custom titanium alloy CNC parts. Many manufacturers now offer tailored services that:

-

Accept custom CAD files.

-

Provide rapid prototyping.

-

Customize materials, tolerances, and surface finishes.

Custom parts are essential where standard off-the-shelf components won’t meet specific geometric or functional requirements. Whether you need unique aerospace brackets, custom medical implant housings, or tailored automotive components, bespoke machining ensures exact standards are met.

The Role of a Titanium Alloy CNC Parts Manufacturer

Selecting the right Titanium alloy CNC parts manufacturer is one of the most important decisions in the supply chain. A quality manufacturer combines:

-

Skilled engineers with machining expertise.

-

ISO-compliant quality systems.

-

Comprehensive inspection methods (e.g., CMM and optical systems).

-

Reliable lead times and global logistics support.

For companies like Xstar, adopting advanced precision machining equipment allows for tight tolerance control, consistent quality, and faster throughput for both small-batch and large-volume orders.

From Factory to Workshop: Production Environments

Whether you’re sourcing from a Titanium alloy CNC parts factory or working directly with a specialized Titanium alloy CNC parts workshop, the environment plays a crucial role in final quality and delivery:

-

Factory Setting: Large-scale production capabilities with extensive machine fleets, ideal for high-volume manufacturing and bulk orders.

-

Workshop Setting: More flexible environments, often better suited for bespoke projects, fast turnarounds, and intricate machining runs.

Both environments can produce premium titanium components — your choice depends on production volume, complexity, and lead-time requirements.

Understanding Titanium Alloy CNC Parts Price and Cost

One of the most frequent questions when sourcing titanium cnc parts is around pricing. Several factors influence Titanium alloy CNC parts price and overall Titanium alloy CNC parts cost, including:

-

Material Grade: Titanium alloys like Grade 5 are more expensive than pure titanium due to strength and performance benefits.

-

Complexity: Parts with intricate features take longer machine time and programming effort.

-

Batch Size: Larger production runs spread setup and programming costs over more units.

-

Surface Finishing: Polishing, anodizing, or other post-processing add to cost.

Because titanium itself is a premium material, known for high production costs but unmatched performance, engineers often balance design needs with production budget early in the process.

Applications of Titanium CNC Parts Across Industries

Titanium components are used widely across key industries:

-

Aerospace: Lightweight structural parts, engine components, and airframe assemblies rely on titanium’s strength and corrosion resistance.

-

Medical Devices: Customized implants and surgical tools benefit from titanium’s biocompatibility.

-

Automotive: High-performance and racing sectors use titanium for weight-critical parts.

-

Industrial Machinery: Corrosion-prone environments require rugged titanium parts.

Each application emphasizes unique design considerations and material properties that make CNC-machined titanium parts preferable.

We are an integrated CNC machining service manufacturer, mainly focused on OEM CNC machining and precision metal parts production. As a professional

titanium cnc parts supplier and

titanium cnc parts manufacturer, we provide stable quality with competitive

titanium cnc parts price for global customers.

Our machining capabilities include

CNC machining aluminum profiles,

CNC machining stainless steel,

CNC machining magnesium alloy,

CNC machining acrylic,

CNC machining ABS, and

CNC machining plastic materials.

We support high-precision CNC solutions for

robot parts machining,

aerospace parts machining,

automotive parts machining, and

medical parts machining across multiple industries.

With high accuracy, fast turnaround, and consistent quality, we provide reliable batch CNC machining services. Contact our CNC machining service factory for detailed pricing information.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.