CNC Machining Aerospace Parts: A Complete Guide to Precision Parts & Suppliers

CNC Machining Aerospace Parts: Precision, Process, and Procurement

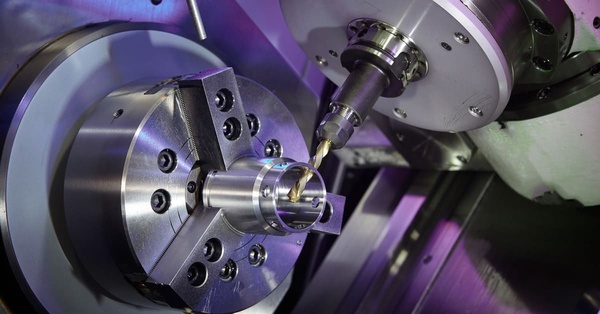

Why cnc machining aerospace parts is core to modern flight

Manufacturers rely on cnc machining aerospace parts to produce mission-critical components that must meet extremely tight tolerances, exacting material specifications, and traceable quality records. Aerospace parts produced via CNC processes — from structural brackets to fuel system housings and engine components — must function reliably under extreme thermal, mechanical, and environmental stress. Meeting standards like AS9100 and maintaining full traceability and certification are non-negotiable for any cnc machining aerospace parts manufacturer.

Aerospace accuracy: tolerances and inspection

The aerospace sector routinely demands tolerances that reach the 0.0001-inch range for some components; therefore, precision machining, CMM inspection, and careful process control are required at every step. Shops that machine aerospace components invest in temperature-controlled environments, certified material sourcing, and documented inspection plans to ensure consistency part-to-part.

Materials and design drivers for cnc machining aerospace parts

Common substrates for aerospace CNC parts include high-strength aluminum alloys (e.g., 7000 series), titanium grades for weight-sensitive structural and engine applications, stainless steels for corrosion resistance, nickel superalloys (for hot sections), and advanced composites for secondary structures. The material choice drives tooling, feeds & speeds, fixturing, and secondary operations like heat treatment or surface finishing. Service providers that advertise aerospace capability typically list the materials they certify and the relevant material certifications they can provide.

The right shop: selecting a cnc machining aerospace parts manufacturer

When selecting a cnc machining aerospace parts manufacturer, buyers look for:

-

AS9100/ISO9001 certifications and a robust quality system.

-

Demonstrated experience with aerospace drawing interpretation, GD&T, and first article inspection (FAI).

-

Capability with multi-axis machining (3, 4, and true 5-axis), Swiss turning for long slender parts, EDM, and precision grinding.

-

Traceability: raw material certificates, batch control, and the ability to issue FAA/EASA/TCCA forms when required.

-

Proven shop processes for complex assemblies and secondary operations (deburring, coating, anodizing, passivation, plating).

How cnc machining aircraft parts are made — process overview

-

Program & Simulation (CAM): Engineering data (STEP, IGES, or native CAD) are imported and CAM programmers create toolpaths optimized for accuracy and thermal control.

-

Fixturing & Setup: Precision fixtures, soft jaws, and modular pallets ensure repeatable referencing for multi-setup parts.

-

Roughing & Semi-Finishing: High-efficiency roughing removes the bulk material while controlling heat; semi-finishing prepares the geometry for final passes.

-

Finish Milling / Turning: Finish passes achieve the final dimensional tolerances and surface finish.

-

Inspection & Certification: CMM reports, surface finish checks, and full documentation (material certs, process logs) complete part release.

Reliable shops combine automated tool-break monitoring, adaptive feeds/speeds, and spindle thermal compensation to keep repeatability within aerospace demands.

Multiaxis machining and complex geometry

True 5-axis milling reduces setups and improves geometric accuracy on complex features — a major advantage when producing parts such as turbine housings, aerodynamic fittings, or single-piece wing components. Modern aerospace shops use multiaxis capability to lower cumulative positional error and shorten lead times for complex geometries.

Typical cnc machine airplane parts and applications

-

Airframe structural components: ribs, spars, longerons, and bulkheads

-

Landing gear and actuator components: housings, pins, brackets

-

Engine components: housings, valve bodies, shafts, and thrust components

-

Fluid and fuel system parts: valves, manifolds, fittings

-

Avionics housings and heat-dissipation parts

Each class of part imposes unique handling: rotating parts need dynamic balancing, hot-section parts need special alloy handling, and flight-control components require very tight GD&T conformance. Fictiv+1

Cost, lead time and scalability considerations

CNC cost drivers include material selection, lot size, complexity (multi-operation vs single-setup), required certification and inspection, and finishing operations. Prototype and low-volume aerospace projects commonly use high-skill shops with flexible setups; production runs benefit from palletized, automated machining centers that reduce unit cost. Buyers should evaluate a manufacturer’s capacity planning and documented on-time delivery performance.

Quality systems and regulatory compliance

Aerospace suppliers maintain strict change control, first article inspection (FAI/AS9102), and configuration management records. For parts to enter certified aircraft, proper paperwork (e.g., 8130-3/EASA Form 1 equivalents when applicable) and chain of custody for materials are required; failure in documentation can lead to rejection at intake or worse, fleet grounding risks.

Best practices: getting the most from your cnc machining aerospace parts supplier

-

Supply detailed CAD with clear GD&T, material callouts, and surface finish notes.

-

Ask for a capability study: machine list, staff qualifications, inspection equipment, and certifications.

-

Use DFMA (design for manufacturability & assembly) reviews to reduce setups and lower unit cost.

-

Plan for post-machining processes: heat treat, shot peen, plating, and paint/coat compatibility.

-

Request sample CMM reports and past performance references for similar components.

Future trends affecting cnc machining aerospace parts

-

Greater integration of additive manufacturing + CNC finishing (hybrid workflows) for topology-optimized structures.

-

Wider adoption of in-process inspection and AI-assisted toolpath optimization to cut cycle times while maintaining tolerance.

-

Expanding use of advanced composites and novel alloys that require new tooling and thermal strategies.

Final takeaway

If you need high-reliability cnc machining aerospace parts, prioritize certified manufacturers with demonstrated aerospace experience, multiaxis capability, material certification, and robust inspection/traceability workflows. A well-chosen cnc machining aerospace parts manufacturer will partner with you on DFMA, reduce lifecycle cost, and deliver parts that meet the unforgiving demands of flight.

We are an integrated CNC machining service factory combining manufacturing and trading, mainly engaged in OEM CNC machining and the production of custom metal components. With solid experience in cnc machining aerospace parts, we deliver stable and high-precision CNC machining solutions for multiple industries.

Our machining capabilities include CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloy, CNC machining acrylic, CNC machining ABS, and CNC machining plastics. These services support CNC precision part production for robot parts machining, aerospace parts machining, automotive parts machining, and medical parts machining, covering the majority of CNC components required in marine and industrial applications.

As a professional provider specializing in cnc machining aerospace parts, our CNC machining services are recognized for high accuracy, fast lead times, consistent quality, and strong process compatibility. To meet different technical and surface requirements, we offer extensive post-processing solutions, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, spray coating, black oxide treatment, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk screening, knurling, and most standard surface finishing processes.

We are a dedicated CNC machining service manufacturer capable of handling batch production orders. If you are looking for a reliable partner in cnc machining aerospace parts or would like to inquire about CNC machining service pricing, please feel free to contact us.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.