Aluminum Machined Components: A Complete Guide to Precision, Processes, and Applications

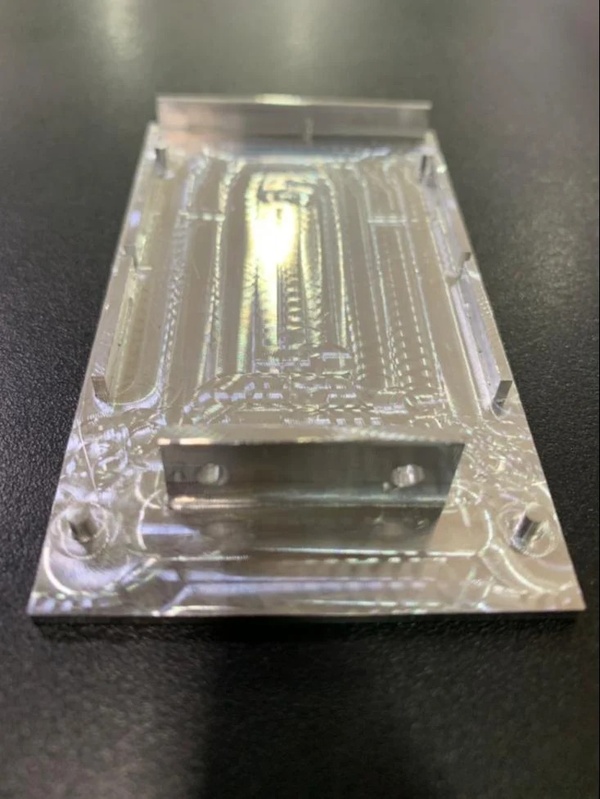

In modern manufacturing, aluminum machined components are essential across industries that demand precision, lightweight performance, and cost-efficient production. From aerospace structures to consumer electronics housings, aluminum machining enables manufacturers to achieve complex geometries with excellent surface quality and dimensional accuracy.

Thanks to aluminum’s favorable properties—such as high strength-to-weight ratio, corrosion resistance, and machinability—aluminum machined components are widely preferred for both prototype development and high-volume production. As CNC technology advances, manufacturers like Xstar continue to push the limits of precision, efficiency, and design flexibility.

Aluminum Machined Components in Modern Manufacturing

What Makes Aluminum Ideal for Machining

Aluminum machined components are produced by removing material from aluminum billets, plates, or extrusions using CNC milling, turning, drilling, and multi-axis machining. Aluminum’s relatively low density and excellent thermal conductivity allow for faster cutting speeds, reduced tool wear, and superior surface finishes compared to many other metals.

Manufacturers rely on aluminum machining to deliver:

-

Tight tolerances for precision assemblies

-

Lightweight structural strength

-

Excellent corrosion resistance

-

Compatibility with anodizing and surface treatments

-

Cost-effective production at scale

These advantages make aluminum machined components a cornerstone of industries such as automotive, aerospace, medical devices, robotics, and industrial automation.

Aluminum Machined Parts: Applications and Design Flexibility

Aluminum machined parts range from simple brackets and enclosures to complex multi-axis components with intricate internal features. CNC machining allows engineers to create custom designs without the limitations often found in casting or forging processes.

Common applications include:

-

Aerospace fittings and housings

-

Automotive engine and transmission components

-

Medical device frames and instruments

-

Heat sinks and electronic enclosures

-

Precision industrial tooling

Because aluminum machined parts can be produced in both low and high volumes, they are ideal for prototyping, functional testing, and mass production.

What Are the Components of Aluminum?

When discussing what are the components of aluminum, it is important to clarify both material composition and finished part structure.

From a materials perspective, aluminum used in machining is typically an alloy composed of aluminum combined with elements such as magnesium, silicon, copper, or zinc. These alloying elements enhance strength, hardness, corrosion resistance, and machinability.

From a manufacturing perspective, the components of aluminum machining include:

-

Raw aluminum stock (billet, plate, or extrusion)

-

Machined features such as holes, slots, threads, and pockets

-

Functional surfaces with defined tolerances

-

Optional surface finishes such as anodizing or coating

Understanding what are the components of aluminum helps engineers select the right alloy and machining strategy for each application.

What Is Machined Aluminum?

Many engineers ask, what is machined aluminum, and how does it differ from other aluminum products?

Machined aluminum refers to aluminum material that has been shaped using subtractive manufacturing processes—primarily CNC machining—to achieve precise dimensions and features. Unlike cast or stamped aluminum, machined aluminum offers superior dimensional accuracy and repeatability.

What is machined aluminum used for?

-

High-precision parts with tight tolerances

-

Components requiring smooth surface finishes

-

Parts that must integrate seamlessly into complex assemblies

-

Custom or low-volume components where tooling costs must be minimized

Machined aluminum is especially valuable in applications where performance and reliability are critical.

How Thin Can Aluminum Be Machined?

A frequent design question is how thin can aluminum be machined without compromising structural integrity or dimensional stability.

The answer depends on several factors, including alloy selection, machining method, part geometry, and tolerance requirements. In many CNC applications, aluminum walls can be machined to thicknesses below 1 mm, and in specialized cases, even thinner sections are achievable.

However, when considering how thin can aluminum be machined, engineers must account for:

-

Vibration and deflection during machining

-

Heat generation and material stress

-

Tool selection and cutting parameters

-

Post-machining handling and assembly loads

Experienced manufacturers like Xstar use advanced fixturing and optimized toolpaths to safely machine ultra-thin aluminum features while maintaining accuracy.

Aluminium Machining Companies: Choosing the Right Partner

Global demand for precision components has led to the growth of specialized aluminium machining companies that focus exclusively on high-quality CNC aluminum production.

When evaluating aluminium machining companies, key criteria include:

-

CNC equipment capabilities (3-axis to 5-axis machining)

-

Experience with multiple aluminum alloys

-

Quality management systems and inspection processes

-

Ability to support prototyping and large-scale production

-

Engineering support and design for manufacturability (DFM)

Reliable aluminium machining companies do more than cut metal—they collaborate with customers to improve part performance, reduce costs, and accelerate time to market.

Aluminium Making Machine Price and Cost Considerations

Another important topic in aluminum manufacturing is aluminium making machine price, which directly affects production economics and supplier capabilities.

The aluminium making machine price varies widely depending on:

-

CNC machine type (lathe, mill, or multi-axis system)

-

Automation level and tooling systems

-

Machine accuracy and spindle performance

-

Brand, configuration, and regional market factors

While advanced CNC machines represent a significant investment, they enable manufacturers to produce aluminum machined components with higher precision, lower scrap rates, and faster cycle times. For customers, working with a well-equipped supplier ensures consistent quality and competitive pricing over the long term.

Industry Benefits of Aluminum Machined Components

The widespread adoption of aluminum machined components is driven by tangible business and engineering benefits:

-

Weight reduction for improved efficiency and performance

-

Design freedom for complex and customized geometries

-

High repeatability across production runs

-

Excellent surface finishes for functional and aesthetic needs

-

Cost efficiency compared to harder-to-machine metals

These advantages explain why aluminum machining continues to expand across both traditional and emerging industries.

Future Trends in Aluminum Machining

As manufacturing technology evolves, aluminum machined components will benefit from:

-

Increased automation and smart CNC systems

-

AI-assisted process optimization

-

Hybrid manufacturing combining machining and additive processes

-

Improved cutting tools for higher speeds and thinner geometries

These innovations will further enhance precision, efficiency, and sustainability in aluminum machining.

We are a professional CNC machining service provider integrating manufacturing and trading, with a primary focus on OEM CNC machining and custom metal part production. Backed by extensive experience in aluminum machined components, we deliver reliable CNC solutions for a wide range of materials and industries.

Our machining scope includes CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloy, CNC machining acrylic, CNC machining ABS, and CNC machining plastics. These CNC processes are widely applied to robot parts machining, aerospace parts machining, automotive parts machining, and medical parts machining, covering most CNC precision components used in marine and industrial sectors.

As an experienced aluminum machined components manufacturer, our CNC machining services are characterized by high precision, fast production cycles, stable quality control, and excellent adaptability across different materials. To further meet customer requirements, we support a comprehensive range of post-processing treatments, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, spray coating, black oxide, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk screening, knurling, and other common surface finishing methods.

We operate as a dedicated CNC machining service factory, offering scalable batch CNC machining services. If you are searching for a dependable aluminum machined components supplier or would like to request CNC machining service pricing, please feel free to contact us for more information.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.