Complete Guide to Advanced Precision Machining: Technology, Leaders, and Real-World Applications

Advanced precision machining is at the core of modern manufacturing excellence. It enables companies to produce highly accurate, complex metal or polymer components for industries such as aerospace, medical devices, automotive, robotics, electronics, and more. By using advanced precision machining technology, manufacturers achieve tighter tolerances, higher performance, and superior surface finishes, which are essential for demanding applications today.

From specialized shops like advanced precision machining inc to regional operators such as advanced precision machining idaho and advanced precision machining longmont co, this article explores the current landscape, essential benefits, and how this technology drives innovation across sectors.

What Is Advanced Precision Machining?

Advanced precision machining refers to highly accurate subtractive manufacturing processes—typically using computer numerical control (CNC) systems—to shape raw materials into precise parts with minimal tolerances and excellent repeatability. This advanced technology integrates multi-axis machining, automation, real-time monitoring, and digital design files to produce components that meet exact specifications.

Key features include:

-

Multi-axis CNC machining for complex geometries

-

Surface quality optimization for performance and longevity

-

Tight tolerance control with micrometer-level precision

-

Real-time process monitoring and automation

-

Rapid prototyping and full-scale production flexibility

These features not only improve manufacturing efficiency but also extend part life and reduce post-processing demands.

Advanced Precision Machining Technology

Central to modern manufacturing, advanced precision machining technology combines cutting-edge hardware, software, and automation. Technologies such as 5-axis CNC mills and high-speed spindles allow machinists to execute complex cuts with high accuracy. Sensors and real-time data analytics optimize operations, while CAD/CAM integration ensures seamless translation from design to production.

This results in:

-

Reduced human error through automation

-

Faster cycle times and setup efficiencies

-

Improved material utilization and less waste

-

Greater consistency across production runs

These benefits make advanced precision machining indispensable for high-specification parts that demand both accuracy and performance reliability.

Leading Service Providers in Advanced Precision Machining

Across the United States and globally, several companies exemplify leadership in advanced precision machining. These firms deliver precision-engineered components tailored to highly regulated industries that demand exacting standards.

Advanced Precision Machining Inc — Precision Partner

Advanced Precision Machining Inc is a respected CNC machine shop known for delivering precision products with an emphasis on accuracy and customer service. They work closely with clients from prototype stages to full-scale production, combining robust machining capability with detailed quality controls and strong communication.

Advanced Precision Machining LLC (Longmont, Colorado)

Located in Colorado, advanced precision machining llc and broadly referred to as advanced precision machining longmont co specializes in precision machining services with nearly two decades of experience. Their facility is equipped with advanced CNC mills and lathes that handle a wide range of materials including steels, exotic metals, aluminum, composites, and plastics, supporting both prototype and high-volume runs.

Industries served include aerospace, medical, renewable energy, scientific instruments, optics, and automotive, demonstrating the versatility of advanced precision machining’s technological value.

Advanced Precision Machining — Boise & Idaho Operations

In the Treasure Valley region, advanced precision machining boise and advanced precision machining idaho represent trusted precision machining services focusing on both local and regional industrial needs. These facilities typically support turning, machining, and finishing processes that contribute to high-precision parts used in robotics, medical tools, or custom equipment.

Specialized Providers: Fabrication and Global Entities

Some companies offer extended capabilities beyond basic machining:

-

Advanced precision machining & fabrication supplies fabricated components along with precise machining, combining machining with structural assembly to deliver comprehensive solutions.

-

Advanced precision machining pte ltd represents international machining expertise, often focusing on global supply networks and specialized precision manufacturing for worldwide clients.

Real-World Uses: Why Advanced Precision Machining Matters

Advanced precision machining has numerous advantages that make it essential across industries:

Enhanced Part Quality and Reliability

Machined parts benefit from consistent precision that ensures repeatability across batches. Tight tolerances and superior surface finish contribute to durability and performance in demanding applications.

Faster Turnaround and Improved Efficiency

Automation and advanced tooling accelerate production, reduce lead times, and support rapid iteration between design and production.

Material Versatility

This machining approach works with a wide spectrum of materials—from aluminum and steel to exotic alloys and engineering polymers—making it suitable for diverse parts and assemblies.

Cost and Waste Reduction

Precision technology reduces material waste by optimizing cuts and minimizing errors, which leads to lower material costs and more sustainable manufacturing.

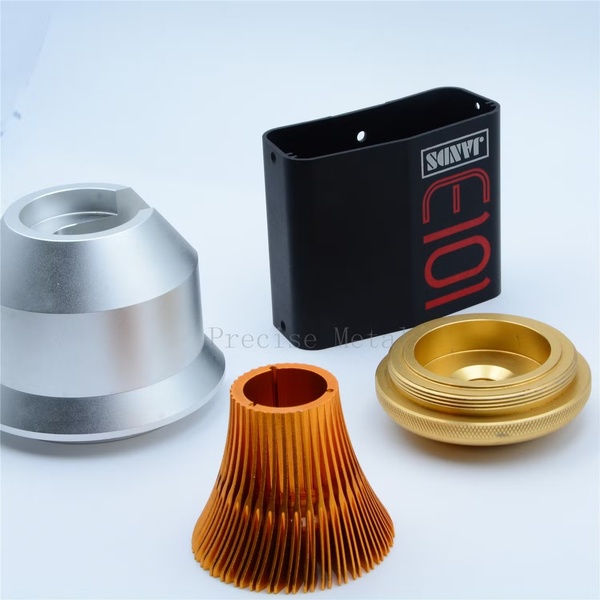

Real Examples & Advanced Precision Machining Photos

Visual portfolios from leading shops often showcase precision components such as aerospace brackets, medical implants, miniature electromechanical parts, and complex housings. These advanced precision machining photos exemplify the tight tolerances and fine details achievable with modern CNC technology.

Images typically highlight:

-

Multi-axis machined parts

-

High surface finish components

-

Prototype vs production parts

-

Tooling setups and CNC machines in action

Reviewing these visuals helps engineers and buyers better understand the level of detail and craftsmanship associated with advanced precision machining.

Future Trends in Precision Machining

As technology evolves, advanced precision machining will continue integrating:

-

Automation and robotics for unmanned production cells

-

AI-assisted optimization and predictive maintenance

-

Integration with additive manufacturing for hybrid processes

-

Real-time sensor feedback and adaptive control systems

These advancements further increase throughput, quality, and adaptability across sectors.

We are an integrated CNC machining service provider combining manufacturing and trading, mainly focused on OEM CNC machining and the production of custom metal components. With solid experience in advanced precision machining, we support the machining of a wide variety of raw materials and complex parts.

Our machining capabilities cover CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloy, CNC machining acrylic, CNC machining ABS, and CNC machining plastics. These services are widely used in robot parts machining, aerospace parts machining, automotive parts machining(/), and medical parts machining, as well as CNC precision components for marine and general industrial applications.

As a professional advanced precision machining manufacturer, our CNC machining services feature high dimensional accuracy, fast production efficiency, consistent quality, and excellent process compatibility. To meet diverse requirements, we offer extensive surface finishing options such as sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, spray coating, black oxide treatment, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk screening, knurling, and most other post-processing techniques.

We are a dedicated CNC machining service factory capable of handling batch CNC machining orders. For customers seeking reliable advanced precision machining solutions or looking to check CNC machining service pricing, please feel free to contact us for more details.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.