Master Guide to Machining Parts Manufacturers in 2026: Choosing the Right Partner for Precision Parts

In the competitive world of precision engineering, machining parts manufacturers play a critical role in delivering high-quality components across industries including aerospace, automotive, medical devices, industrial equipment, electronics, and more. Whether you are sourcing simple parts or complex assemblies, understanding how to evaluate and choose the right machining partner is essential for performance, cost-effectiveness, and timely delivery.

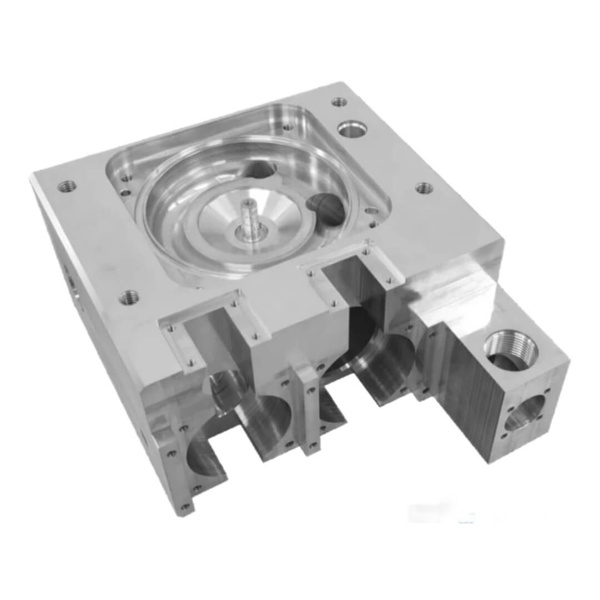

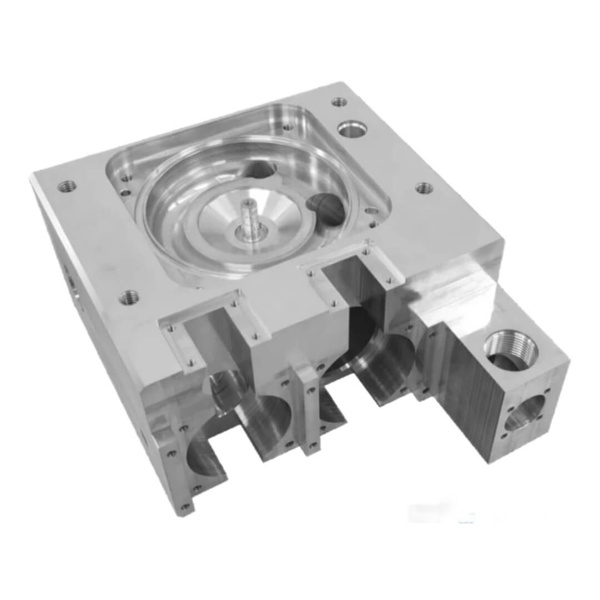

At its core, a machining parts manufacturer uses tools such as CNC machines, lathes, milling centers, drills, and advanced measuring systems to transform raw materials into precision machine parts with tight tolerances and dependable performance standards.

What Defines a Top-Tier Machining Parts Manufacturer

When evaluating machining parts manufacturers, several key capabilities set leading companies apart:

Precision and Quality Standards

Precision is at the heart of machining parts production. Reputable machining parts manufacturers must maintain strict quality controls, often with certifications such as ISO 9001 or industry-specific standards. Accurate measurement tools like Coordinate Measuring Machines (CMM) and optical inspection systems ensure parts meet design specifications down to microns.

Versatile Material and Technology Expertise

Advanced machining partners can work with a range of materials including aluminum, stainless steel, titanium, brass, engineering plastics and more. They leverage CNC machining, Electrical Discharge Machining (EDM), grinding, polishing, turning, and milling processes to meet diverse engineering requirements.

Scalability and Production Volume Support

From prototype runs to full-scale production, reliable machining parts suppliers provide scalable solutions. They should have the capacity and workflow to support both low-volume and high-volume manufacturing without quality compromise.

Lead Time and On-Time Delivery

Efficient scheduling and streamlined production workflows are vital. Strong machining parts manufacturers optimize processes to shrink lead times while ensuring on-time delivery to support both just-in-time supply chains and project deadlines.

Machining Parts Manufacturers in India: Cost-Effective Precision Solutions

Machining Parts Manufacturers in India

India has rapidly emerged as a global hub for machining parts manufacturers in India thanks to competitive pricing, skilled labor, and growing manufacturing infrastructure. Companies here specialize in CNC machining, turning, milling, and custom fabrication for critical components used across industries such as automotive, aerospace, and heavy equipment.

Many Indian machining partners support end-to-end services including CAD/CAM design consultation, prototyping, and mass production. India’s strong export networks allow these machining partners to serve global clients while maintaining cost-effective pricing and reliable quality control systems.

Regional Spotlight: Machine Parts Manufacturers in Bangalore and Ahmedabad

Machine Parts Manufacturers in Bangalore

In southern India, machine parts manufacturers in Bangalore combine advanced manufacturing technologies with engineering expertise. Bangalore’s manufacturing ecosystem caters particularly to electronics, aerospace, and defense sectors, providing precision CNC machining with stringent adherence to international quality norms.

Machine Parts Manufacturers in Ahmedabad

The western industrial belt of Gujarat, particularly machine parts manufacturers in Ahmedabad, is known for robust metalworking capabilities and diversified production lines. Ahmedabad’s manufacturing ecosystem supports high-precision turning, multi-axis milling, and heavy-component machining for both domestic markets and international OEMs.

Machining Parts Supplier: What to Look For

Selecting the right machining parts supplier involves more than price comparison. A strong supplier should exhibit:

-

Proven capability in diverse machining processes (CNC, EDM, grinding)

-

Advanced material handling and finishing options

-

Quality assurance systems with traceable inspection records

-

Responsive communication and engineering support

-

Ability to handle custom orders and flexible batch sizes

Strong suppliers support both prototype stages and full-scale production with consistent quality and delivery reliability.

Global Leaders: Machine Parts Manufacturer in USA

In North America, a machine parts manufacturer in USA often focuses on high-precision CNC machining for aerospace, defense, medical, and industrial automation sectors. U.S. manufacturers emphasize strict adherence to quality standards, advanced CNC equipment, and rapid turnaround processes to meet demanding specifications. Domestic machining suppliers also provide strong customer support and engineering co-design to ensure parts meet performance targets.

Specialty Considerations

Machine Parts Manufacturing HSN Code

For businesses importing or exporting machined components, understanding the machine parts manufacturing HSN code is essential for compliance and customs classification. HSN codes help categorize machine parts accurately to determine duty rates, regulatory requirements, and trade documentation.

Local Search: Machine Parts Manufacturer Near Me

In today’s connected world, engineers often search for machine parts manufacturer near me to find nearby suppliers capable of faster logistics, easier visits, and tighter coordination. Local machining partners can provide rapid prototyping, on-site quality checks, and flexible scheduling—key benefits for time-sensitive projects.

Best Practices for Partnering With Machining Parts Manufacturers

To maximize success when working with machining parts manufacturers:

-

Share clear, detailed CAD designs and technical specifications

-

Ask for material certifications and quality control documentation

-

Evaluate manufacturer experience in your industry segment

-

Prioritize partners with strong engineering collaboration capabilities

-

Verify delivery timelines, logistics support, and risk-mitigation plans

Choosing the right machining partner early in the project lifecycle can save time, reduce costs, and ensure final parts align with performance expectations.

Conclusion

Machining parts manufacturers form the backbone of modern precision manufacturing, transforming raw materials into high-performance parts through meticulous engineering, advanced machinery, and rigorous quality controls. Whether you’re engaging machining parts manufacturers in India, sourcing a machine parts manufacturer in USA, or seeking a machining parts supplier nearby, informed selection based on capability, quality, and reliability pays dividends in product success.