How High Volume CNC Machining Services Help Scale Production

High Volume CNC Machining — Precision, Scale & Smart Manufacturing

When production demands are high and tolerance requirements are strict, high volume CNC machining becomes a strategic cornerstone for manufacturing success. At Xstar, we support manufacturers, product developers, and engineers with scalable, precise machining solutions — from prototypes to thousands of parts. In this article you’ll learn what high volume CNC machining is, how it compares to conventional approaches, where precision matters most, and the advantages of working with a dedicated high volume machine shop.

What Is High Volume CNC Machining?

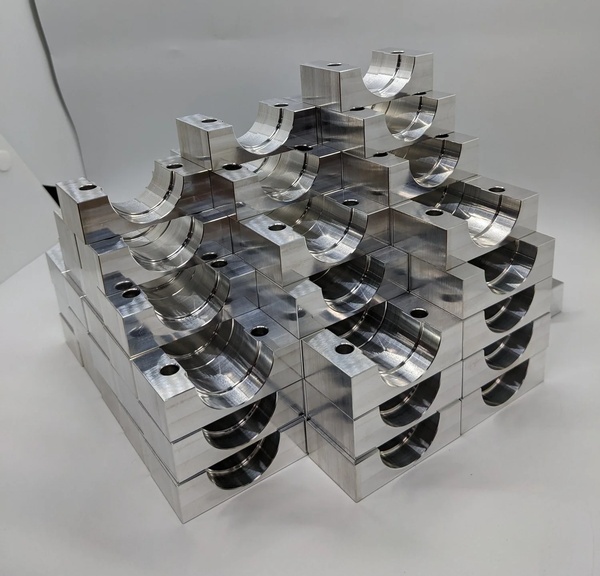

High volume CNC machining refers to the process of producing large quantities of machined parts using computer numerical control (CNC) equipment. Rather than making parts one-by-one, manufacturers set up fixtures, tooling, and automated workflows that enable repeated, consistent production runs — often in the hundreds, thousands, or more. This is especially valuable for industries like automotive, aerospace, medical devices, and consumer electronics where consistency and throughput are critical.

Because these parts must maintain strict dimensional tolerances and surface finishes across every unit, high volume CNC machining integrates optimized programming, quality inspection systems, and efficient tooling paths to keep parts uniform from batch to batch.

High Volume CNC Machining Services — Scale with Precision

When you need parts at scale, high volume CNC machining services take on the planning, setup, machining, and quality assurance required for bulk production. Unlike small-batch or prototype work, high volume production demands:

-

Repeatable accuracy across all units

-

Tool life management to reduce variation

-

Automated loading/unloading where possible

-

Robust quality control (often with in-process inspection)

These services are often provided by a high volume machine shop with multiple CNC mills, lathes, and 5-axis centers configured to run continuously. By pooling capacity and expertise, these shops deliver high throughput while minimizing defects and lead times.

CNC vs Conventional Machining — Key Differences

A common question is cnc vs conventional machining: which is better, and when?

-

Conventional machining relies on manual operation and setup — often slower and more dependent on operator skill.

-

CNC machining is computerized, repeatable, and scalable, making it ideal for complex parts and high volume production.

In high volume environments, CNC excels because once the program is tested and validated, it can run with little human intervention. This reduces variability and shortens turnaround, especially when compared with conventional manual machinists cutting parts one at a time.

What Is CNC Precision Machining?

Precision is at the heart of high volume CNC work. But what is CNC precision machining? It refers to CNC processes that achieve very tight tolerances — often in the thousandths of an inch or microns — with consistent surface finish quality.

Precision machining uses:

-

High-quality tooling and holders

-

Sophisticated machine motion control

-

Multi-axis capabilities (3, 4, or 5 axes)

-

Feedback systems for consistency

In high volume settings, precision machining ensures that every part — not just the first sample — meets design criteria.

High Volume Machining in Practice

High volume machining often integrates:

-

CNC lathe and milling centers dedicated to specific part families

-

Fixtures designed for fast part changeovers

-

Automated tool changers and coolant systems

-

In-line inspection stations

This configuration reduces idle time and maximizes throughput, critical for high demand industries.

Career Path: Is CNC Machining a Good Career?

The growth of automated manufacturing naturally leads to questions like is CNC machining a good career? The answer is yes — especially as demand for precision parts increases globally. Careers in CNC machining offer:

-

Stable demand across multiple industries

-

Technical challenge and skills growth

-

Opportunities in programming, maintenance, inspection, and supervision

-

Competitive salaried roles and specialization paths

High volume environments also create roles in process engineering, quality control, and automation — expanding beyond traditional machine operation into higher-level skill sets.

Supporting High Volume CNC Milling

A major operation in volume production is high volume CNC milling — typically used for prismatic parts, housings, engine components, and structural pieces. CNC milling in high volume hinges on:

-

Efficient tool paths to minimize cycle time

-

Tool life monitoring to reduce changeovers

-

Coolant and chip management for continuous operation

Xstar’s partners optimize milling programs to balance speed and surface finish, ensuring every part meets design requirements over long runs.

Where to Find Support & Training

If you’re new to CNC machining or want to expand your skills, consider local training programs or a cnc machining course near me to build foundational knowledge. Such courses cover CAD/CAM basics, tool selection, machine setup, and operation — all essential before scaling to high volume machining.

Likewise, when you need part production, searching for custom CNC machining near me helps you find local service providers who can take your design from concept to high volume reality.

As a manufacturing-and-trading integrated supplier specializing in CNC machining services, our company focuses on contract CNC production and the precision fabrication of a wide variety of metal parts. We offer machining capabilities for

CNC machining aluminum profiles,

CNC machining stainless steel,

CNC machining magnesium alloy,

CNC machining acrylic,

CNC machining ABS, and

CNC machining plastic materials.

Our expertise also covers advanced component processing for

robot machining,

aerospace part machining,

automotive component machining, and

medical part machining,

meeting the demanding precision needs of many industrial sectors.

We deliver CNC machining solutions with outstanding accuracy, fast turnaround, stable quality, and excellent compatibility for different material and structural requirements. A full selection of post-processing options is available, such as sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum coating, electroless plating, phosphating, passivation, silk printing, and surface texturing.

As a dedicated CNC machining manufacturer, we provide large-batch CNC production services. If you would like to request CNC machining service pricing, feel free to reach out to us anytime.

Below are the internal links related to

high volume cnc machining product,

high volume cnc machining manufacturer,

and high volume cnc machining as a price term.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.