How to Choose Custom Sheet Metal Fabrication Near Me — Local & Online Options

Custom Sheet Metal Fabrication: Precision, Flexibility and Real-World Solutions by Xstar

When off-the-shelf metal parts don’t suit your design, application, or aesthetic needs, custom sheet metal fabrication becomes the solution. At Xstar, we specialize in transforming raw metal sheets into precisely engineered parts — from enclosures and cabinets to structural components and bespoke assemblies. Whether you need one prototype or a small batch, our custom sheet metal fabrication services give you flexibility, quality and full control over materials and specifications.

What is custom sheet metal fabrication?

Custom sheet metal fabrication refers to the process of taking flat metal sheets (steel, stainless steel, aluminum, etc.), cutting or shaping them, bending or forming, and then assembling (welding, riveting, fastening) — often followed by finishing (powder-coating, painting, plating, polishing) — to create parts or assemblies tailored to your design. Unlike standard, mass-produced metal parts, every piece is made to order, matching your drawings or CAD specifications, with precision and adaptability.

The capabilities of top custom sheet metal fabrication services

High-quality custom sheet metal fabrication services typically offer:

-

Sheet cutting and shaping: laser cutting, water-jet, shearing, etc. to cut raw sheets into required shapes.

-

Bending / forming / folding: to give sheets proper shape, angles, and structural geometry.

-

Welding / assembly / joining: when multiple pieces need to be assembled into a housing, frame, enclosure or complex structure.

-

Secondary operations & finishing: such as powder coating, painting, plating, polishing — for protection, aesthetics or compliance.

-

Prototyping & small batch production: offering flexibility from single prototypes to small-medium runs.

Because of this comprehensive capability, custom sheet metal fabrication is ideal for housing enclosures, industrial cabinets, architectural metalwork, HVAC ducts, machine guards, decorative metal panels, structural brackets — basically any scenario where off-the-shelf metal parts won’t do.

Local, Online and Global Options — Matching the Right Service

Depending on your needs, you can choose from several modes:

-

Custom sheet metal fabrication near me — local workshops or fabrication shops are ideal when you need close communication, sample inspection, installation support, or fast turnaround for prototypes and small jobs.

-

Custom sheet metal fabrication online — for remote clients or when shipping is acceptable; you upload drawings or CAD files, specify material, finish and quantity; receive parts delivered to your door.

-

Custom sheet metal fabrication China (or overseas) — for clients seeking cost advantages, larger capacity or willing to trade longer shipping time for potential savings; suitable especially for batch production or less time-sensitive projects.

At Xstar, we coordinate all options — whether you prefer nearby shops for quick jobs or online/overseas fabrication for bulk or cost-sensitive projects.

Considering Cost & Value — custom sheet metal fabrication cost

When evaluating custom sheet metal fabrication cost, several factors matter:

-

Material type and thickness (steel, stainless steel, aluminum — each with different cost and handling requirements).

-

Complexity of geometry: simple flat boxes cost less than complex enclosures with cutouts, bends, welds.

-

Quantity: prototypes or single units are costlier per piece than small batches or series.

-

Finishing and secondary processes: powder-coating, plating, painting, polishing add to cost.

-

Labor and processing time: intricate bending, welding, tight-tolerance assembling increase labor/complexity cost.

By working with a manufacturing partner like Xstar, you get transparent quoting: breakdown of material, labor, finishing and delivery costs — allowing you to make informed decisions balancing quality, cost, and lead time.

Real-world examples and use cases

-

A startup building custom electronic enclosures could request custom sheet metal fabrication services: CNC-cut panels, bent frames, welded seams, powder-coated finish — delivered turnkey.

-

Architectural / interior design firms needing custom sheet metal fabrication Calgary or custom sheet metal fabrication Toronto for decorative metal panels, stair railings, custom structures — shipped or made locally depending on location.

-

Small machinery or equipment builders seeking housings, guards or frames — custom sheet metal fabrication near me or fabrication online provide accessible options without large tooling cost.

-

Businesses seeking cost-effective production opting for sheet metal fabrication overseas, such as custom sheet metal fabrication China, to benefit from economies of scale for larger orders.

Why choose Xstar for your sheet metal fabrication needs

At Xstar, we aim to provide a full-service approach:

-

Design & Specification Support — we assist with design review, material selection, bends, tolerances, finish.

-

Flexible Fabrication Network — we match your job to the best shop, whether local or remote, prototype or batch.

-

Quality Control & Finishing — ensure weld integrity, accurate bends, consistent finish, and final inspection before delivery.

-

Transparent Pricing & Delivery — detailed cost breakdown, clear lead times, reliable packaging and logistics.

-

Customer-focused Service — whether you’re building one custom cabinet or commissioning dozens of enclosures, Xstar ensures consistency, communication, and satisfaction.

Summary

In a world where off-the-shelf metal parts often fall short, custom sheet metal fabrication — especially when managed by a capable provider like Xstar — gives you the precision, flexibility, and comprehensive service your project deserves. From single prototypes to small batch runs, from simple enclosures to intricate structural components, custom sheet metal fabrication turns your design vision into metal reality.

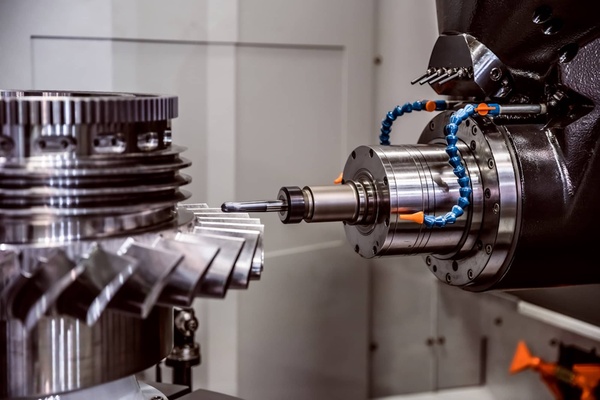

As a combined manufacturing and trading company, we specialize in CNC production services, primarily focusing on CNC subcontract machining and the precision manufacturing of various metal components. Our capabilities extend across multiple materials and industries, supported by our commitment to delivering reliable custom sheet metal fabrication, high-quality custom sheet metal fabrication manufacturer solutions, and competitive custom sheet metal fabrication price options.

We provide machining for a wide range of materials, including aluminum profile CNC machining, stainless steel CNC machining, magnesium alloy CNC machining, acrylic CNC machining, ABS CNC machining, and plastic CNC machining. Our services also cover advanced applications such as robotics machining, aerospace parts machining, automotive parts machining, and medical parts machining, enabling us to support the manufacturing needs of industrial, engineering, and high-precision sectors.

Our CNC machining solutions deliver excellent accuracy, fast turnaround, stable quality, and broad compatibility with diverse product designs. A full selection of post-processing options is available, including sandblasting, hard anodizing, micro-arc oxidation, polishing, grinding, painting, blackening, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk printing, and textured finishing.

As a dedicated CNC machining supplier, we offer both small-batch and mass-production services. For inquiries regarding custom sheet metal fabrication, trusted custom sheet metal fabrication manufacturer services, or an updated custom sheet metal fabrication price, feel free to reach out to us anytime.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.