Steel Metal Fabrication: Processes, Capabilities, and Global Service Considerations

Steel metal fabrication encompasses a range of industrial processes used to transform steel materials into functional parts, assemblies, and structures. These operations support diverse sectors, including construction, heavy equipment, energy, transportation, machinery, and specialized industrial applications. As project requirements expand in precision, durability, and production scale, steel metal fabrication continues to evolve through advanced equipment, improved material standards, and tighter process control.

Steel Metalworking and Fabrication Processes

Steel metalworking remains the foundation of fabrication activities. It includes cutting, forming, machining, welding, and finishing processes designed to modify raw steel into engineered products. Modern fabrication environments utilize a combination of manual and automated technologies:

-

Laser cutting, plasma cutting, and water-jet cutting for material separation.

-

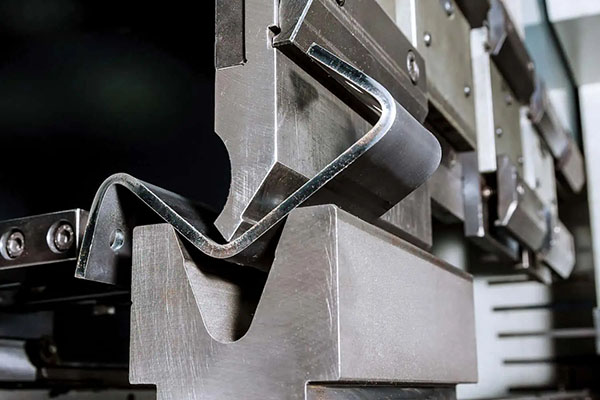

CNC press brake forming for controlled bending operations.

-

Manual and robotic welding for structural and precision assemblies.

-

Surface finishing technologies, including coating, painting, and protective treatments for corrosion resistance.

These operations contribute to the overall precision and structural integrity of fabricated components. In many facilities, steel metalworking is supplemented by digital modeling, engineering consultation, testing, and fabrication documentation to ensure predictable outcomes across production batches.

Steel Metal Fabrication Shop Near Me

When assessing a steel metal fabrication shop near me, core evaluation points include technical capability, material inventory, production capacity, and quality control systems. Shops may vary significantly in their specialization: some focus on thin-gauge sheet steel, while others handle heavy structural components, large weldments, or architectural steel products.

Local availability is often a decisive factor for projects requiring rapid prototyping, site fitting, or coordinated installation, but technical capability remains the primary determinant. A full-service shop generally provides integrated cutting, forming, welding, assembly, and finishing operations supported by engineering documentation and materials certification.

Steel Metal Fabrication Companies

Across regions, steel metal fabrication companies typically offer end-to-end services, from design evaluation to final product delivery. Common differentiators among these companies include:

-

Range of supported materials (mild steel, alloy steel, stainless steel)

-

Automation level and types of fabrication equipment

-

Welding qualifications and certifications

-

Dimensional inspection and quality assurance systems

-

Experience in specific industries (construction, machinery, transportation, energy)

Organizations such as Xstar typically follow standardized fabrication workflows, enabling consistent performance on diverse project types. Some companies also integrate supply-chain sourcing, allowing them to support high-volume production and specialized material requests.

Steel Metal Fabrication Near Me

The phrase steel metal fabrication near me often relates to logistical planning and project coordination. Local resources reduce transport time, simplify communication, and allow for direct quality verification. However, proximity should be considered alongside core requirements such as accuracy, structural compliance, and documented material properties. Many industrial projects, particularly those involving structural loads or regulatory compliance, require a fabricator that meets formal inspection standards regardless of location.

Steel Metal Fabrication Companies Near Me

For buyers evaluating steel metal fabrication companies near me, the selection process typically includes reviewing equipment capabilities, past project records, inspection procedures, and sustainability practices. Companies offering multi-material support, integrated machining, or certified welding capabilities may provide advantages for complex assemblies or high-precision fabrication. Factors such as lead time, adaptability to design changes, and long-term production stability influence procurement decisions as well.

Steel Metal Fabric Fabrication Practices and Material Considerations

The term steel metal fab generally refers to practical, production-focused fabrication work involving mild steel, structural steel, alloy steel, and sometimes stainless steel. Material selection affects fabrication parameters, including cut speed, weld penetration, rigidity, corrosion behavior, and finishing requirements.

Mild steel is typically used for structural and general fabrication due to its weldability and cost efficiency. Alloyed steels offer enhanced strength or temperature resistance. Stainless steel requires controlled handling to maintain surface quality and prevent contamination, making it suitable for environments requiring corrosion resistance, sanitation, or decorative finishing.

Stainless Steel Metal Fabrication Near Me

Projects requiring corrosion resistance, sanitary surfaces, or aesthetic finishing often rely on stainless steel metal fabrication near me. Stainless steel fabrication demands:

-

Controlled heat input to prevent distortion

-

Proper separation of stainless and carbon-steel tooling areas

-

Surface finishing and passivation when required

-

TIG/MIG welding techniques tailored to stainless alloys

Fabricators experienced with stainless steel typically maintain designated work zones, specialized tooling, and post-treatment capabilities for achieving consistent surface quality.

Steel Metal Fabrication Services in India

Demand for steel metal fabrication services in India continues to expand across infrastructure, energy, automotive, and industrial equipment sectors. India’s fabrication capabilities range from small workshops to full-scale manufacturing facilities equipped with CNC lasers, robotic welders, advanced forming machinery, and large-volume production lines.

Offshore fabrication is often considered for high-volume or cost-sensitive projects. When collaborating with providers in India, organizations typically evaluate:

-

Material certifications

-

Welding and inspection standards

-

Quantity scalability

-

Export packaging and logistics

-

Consistency of dimensional tolerance across batches

Brands like Xstar engage with both local and international partners to support engineering requirements, compliance expectations, and consistent production management.

Technology, Quality Control, and Industry Compliance

Fabrication environments increasingly rely on advanced inspection tools such as digital measurement systems, laser scanners, and automated quality-recording frameworks. Compliance with ISO welding standards, material traceability, and dimensional verification supports applications in industries requiring strict safety and performance criteria.

Documentation—such as welding procedure specifications (WPS), inspection reports, and certified material test reports (MTR)—remains an essential part of steel metal fabrication workflows. These measures ensure that fabricated components meet regulatory and operational requirements.

Conclusion

Steel metal fabrication continues to advance through improved material standards, automated production technologies, and enhanced quality assurance systems. Whether sourced locally or internationally, the selection of fabrication partners requires attention to capability, repeatability, material expertise, and documented quality. As industries expand and project requirements increase in complexity, comprehensive fabrication support becomes essential to ensure safe, reliable, and efficient project execution.

We are an integrated manufacturing and trading company specializing in CNC machining services, mainly focused on contract CNC production and the machining of various metal components. As a professional provider of steel metal fabrication products, steel metal fabrication manufacturers, and steel metal fabrication price information, we deliver reliable and high-precision custom machining solutions for diverse industries.

Our machining capabilities include aluminum extrusion CNC machining, stainless steel CNC machining, magnesium alloy CNC machining, acrylic CNC machining, ABS CNC machining, and plastic CNC machining. We also provide advanced processing services for robot component machining, aerospace parts machining, marine parts machining, automotive parts machining, and medical parts machining, meeting the precision requirements of a wide range of industrial applications.

Our CNC machining services deliver high accuracy, fast production efficiency, stable quality, and strong compatibility across different project needs. We support an extensive list of post-processing options, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, chemical plating, phosphating, passivation, silk-screen printing, and textured finishing.

As a dedicated CNC machining service manufacturer, we offer both prototype and large-scale CNC production. If you need CNC machining service pricing or want to discuss a custom manufacturing project, feel free to contact us.