Brass CNC Milling & Cutting: Best Practices for High‑Quality Brass Parts

Brass CNC Machining: Precision Brass Components with Xstar

In modern manufacturing — from plumbing fixtures and musical instruments to industrial valves and decorative hardware — brass CNC machining remains a top choice for producing precision metal components that combine machinability, corrosion resistance, and aesthetic appeal. With expert providers like Xstar, brass CNC machining becomes a streamlined process delivering high-quality parts for a wide range of applications.

Why Choose Brass for CNC Machining

Brass offers several advantages that make it especially suitable for CNC machining: good machinability, excellent thermal conductivity, corrosion resistance, and attractive appearance. These characteristics mean that parts produced through brass CNC machining are not only functional and durable, but also often require less finishing and post‑processing compared with harder metals.

Because brass is relatively softer than steel or stainless steel, tools wear more slowly, and surface finish tends to come out smooth. That’s why many businesses rely on brass cnc machining services when they need reliable, high-precision brass components for valves, fittings, decorative hardware, gears, instrument parts, or custom components.

For companies such as Xstar, offering full-service brass CNC machining services ensures that clients get consistent craftsmanship, material sourcing, machining, finishing, and inspection — all in one place.

Common Uses for Brass CNC Machined Parts

Brass CNC machining parts are widely used across sectors:

-

Plumbing and fluid-handling components: valves, fittings, connectors.

-

Decorative hardware and architectural elements: handles, trim, fixtures.

-

Mechanical components: small gears, shafts, bushings.

-

Instrument and electronics housings, terminals or connectors.

-

Custom prototypes and small-batch parts for niche applications.

Thanks to its machinability and cost-effectiveness, brass CNC machined components remain a go-to choice in small-volume manufacturing and custom design jobs.

Overview of Brass CNC Machining Process

Design and Preparation

Good machining begins with smart design — before any machining starts, engineers plan the part geometry, wall thicknesses, hole placements, and tolerances. When you work with brass cnc cutting design or brass cnc cutting service, design considerations often include avoiding overly thin walls, ensuring adequate support when cutting or milling, and allowing for proper chip evacuation.

For example, if you request a bracket or housing to be made via brass CNC machining, the design must accommodate machining constraints: fillets for internal corners, straight accessible surfaces for milling, and clearance for clamps or fixtures. These steps help minimize deformation or chatter during machining.

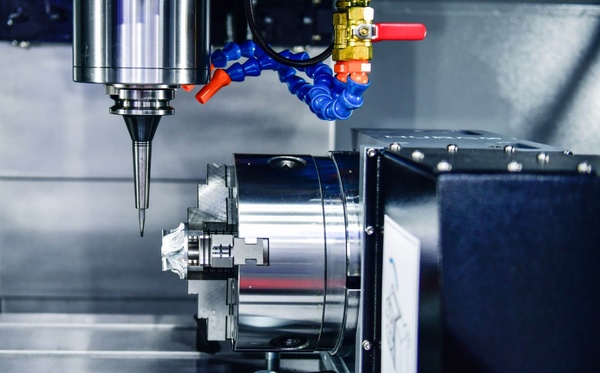

CNC Cutting and Milling

For many parts, machining starts with brass cnc cutting — rough cutting or sawing brass blocks or billets — then transitions into brass cnc milling to create features such as slots, pockets, threads, precise holes, and complex contours.

Using a cnc brass mill center, machinists can perform multi‑axis operations to achieve intricate geometries and tight tolerances. Because brass machines easily, feed rates and spindle speeds can be optimized for efficiency while preserving tool life.

If you only require flat parts — like flanges or plates — a well-calibrated brass cnc cutting service can cut brass sheets or plates to size, followed by light milling or drilling operations to finish.

Post‑Processing and Finishing

After machining, many brass components benefit from finishing processes: polishing, plating, chamfering, or passivation — especially for decorative or exposed parts. Good finishing enhances both appearance and corrosion resistance. Full-service providers offering brass CNC machining services typically integrate finishing and inspection into their workflow, reducing lead time and quality risk.

Best Practices for High‑Quality Brass CNC Machined Components

Design for Manufacturability

-

Avoid very thin walls or narrow ribs — they can distort or vibrate when milled.

-

Use standard hole sizes and thread standards where possible to simplify tooling.

-

Provide generous fillets and rounded internal corners to ease tool path and reduce stress concentration.

-

Ensure sufficient material around mounting points and critical features to maintain structural integrity.

These good practices — often part of a brass cnc cutting design phase — help ensure that the final brass cnc machined components meet expectations for precision, strength, and finish.

Choosing the Right Service Provider

When you select a vendor for brass CNC machining services, consider:

-

Their ability to handle material sourcing, CNC programming, machining, finishing and inspection as a full service.

-

Their experience with brass material — tool selection, coolant usage, chip control.

-

Their capacity to deliver consistent tolerances, especially for high-precision parts.

-

Their turnaround time, quality documentation, and communication throughout the process.

Organizations like Xstar combine these capacities to deliver reliable brass CNC machined parts — whether for prototypes, small-batch production, or custom components.

Common Applications and Industries

Thanks to its unique material properties and machining convenience, brass CNC machined components serve many industries:

-

Plumbing & fluid control: valves, connectors, fittings — benefits from brass’s corrosion resistance and machinability.

-

Decorative hardware & architecture: handles, knobs, trim — where brass’s aesthetic and finish matter.

-

Mechanical & industrial equipment: bushings, shafts, small precision gears — for strength and wear resistance.

-

Electronics & instrumentation: housings, connectors, terminals — due to brass’s conductivity and machinability.

-

Custom and prototype parts: short-run production where flexibility and speed matter more than high-volume economies.

For these use cases, employing brass CNC machining offers a balance between performance, cost, and manufacturability.

Why Brass CNC Machining Remains Popular

Even in a world increasingly using advanced composites and polymers, brass CNC machining remains relevant because:

-

Brass is easier to machine than many metals, reducing tooling cost and machining time.

-

It delivers good mechanical properties and corrosion resistance, satisfying functional requirements.

-

The appearance and finish of brass suit decorative or visible parts.

-

The process is flexible, ideal for both prototypes and small to medium production runs.

-

Full-service providers offering brass CNC machining services simplify sourcing, production and inspection.

With these advantages, brass CNC machining continues to be a go-to for precision brass parts manufacturing — and partners like Xstar ensure quality, consistency, and service.

Summary & Recommendations

If you’re planning to design or produce brass parts, using brass CNC machining is likely your best bet. By collaborating with an experienced provider for brass cnc machining services, you get access to material sourcing, robust brass cnc cutting design, precise brass cnc milling, and careful finishing — all in one controlled process. The result: high-quality brass cnc machined components that meet both functional and aesthetic demands.

To maximize success:

-

Design parts with manufacturability in mind (avoid very thin walls, provide fillets, plan for tool access).

-

Provide clear specifications (tolerances, finish, material grade).

-

Choose a vendor who offers end-to-end service — from material to finished part.

-

For small-batch or custom parts, brass CNC machining offers both speed and cost-effectiveness.

With these steps, you can rely on brass CNC machining to deliver parts that meet expectations — and stand the test of time.

We are an integrated manufacturing and trading company specializing in brass cnc machining services. Our primary focus is on contract CNC machining and precision production of a wide range of metal components. We provide professional machining for aluminum CNC machining, stainless steel CNC machining, magnesium alloy CNC machining, acrylic CNC machining, ABS CNC machining, and plastic CNC machining, covering both metal and plastic raw materials.

Our CNC capabilities extend across various industries, producing high-precision parts for robot parts machining, aerospace parts machining, marine parts machining, automotive parts machining, medical parts machining, and general industrial applications. Our services guarantee high accuracy, fast turnaround, stable quality, and excellent material compatibility.

We also offer a comprehensive range of post-processing options, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, chemical plating, phosphating, passivation, silk printing, and textured finishing.

As a professional brass cnc machining manufacturer, we provide batch CNC machining services. For more information about brass cnc machining, manufacturer details, or brass cnc machining pricing, please feel free to contact us.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.