CNC Swiss Precision Machining: High-Accuracy Manufacturing Solutions by Xstar

In today’s competitive manufacturing world, industries such as medical, aerospace, automotive, and electronics rely heavily on components that demand exceptional precision, smooth finishes, and consistent repeatability. CNC Swiss precision machining—also known as Swiss-type turning—has become one of the most powerful solutions for producing miniature, complex, and tight-tolerance parts at scale.

At Xstar, we specialize in delivering high-accuracy Swiss machining services that combine advanced technology, multi-axis performance, and automated bar-feeding systems to meet the world’s most demanding engineering requirements.

What Is CNC Swiss Precision Machining?

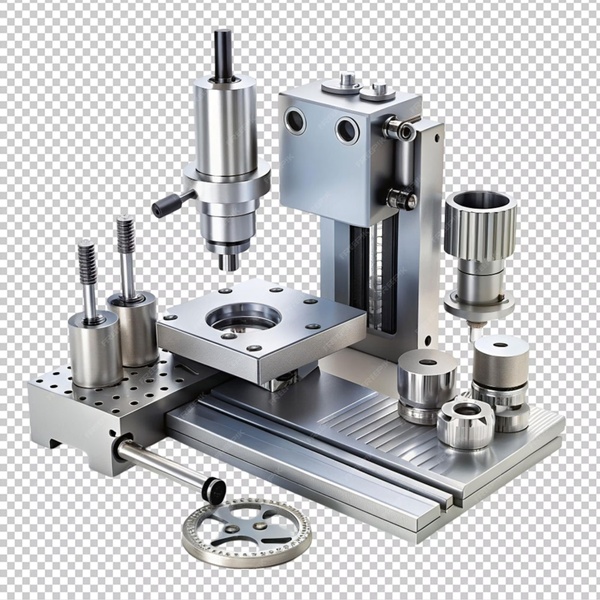

CNC Swiss precision machining is a unique turning technology originally developed for producing watch components in Switzerland. Unlike traditional CNC lathes, a Swiss machine uses a guide bushing to support the bar stock extremely close to the cutting tool. This design minimizes vibration and deflection, ensuring superior accuracy even on very long, slender, or micro-sized components.

Key differentiators include:

-

The material moves while the tools remain stationary

-

Multi-axis live tooling performs turning, drilling, milling, and threading in one setup

-

Automated bar feeders enable continuous, lights-out production

-

Capable of holding tolerances as tight as ±0.0001 inch (±0.0025 mm)

This architecture makes Swiss machining ideal for industries where precision and miniature geometries are essential.

Key Benefits of CNC Swiss Precision Machining

1. Ultra-Tight Tolerances

The guide-bushing structure stabilizes the material close to the cutting zone, enabling exceptionally high dimensional accuracy and repeatability. This is critical for medical implants, aerospace fasteners, micro-connectors, and instrumentation components.

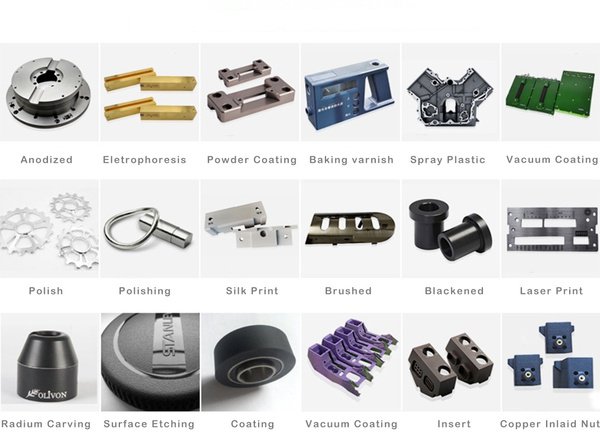

2. Superior Surface Finish

The reduced vibration results in a smooth, refined surface quality that often eliminates the need for secondary polishing or finishing processes.

3. Multi-Axis, Single-Setup Machining

Swiss machines support simultaneous operations such as turning + drilling or milling + threading. Complex geometries can be produced in one cycle, minimizing setup time and ensuring consistency.

4. High-Volume Efficiency

With automated bar feeding and stable cutting conditions, Swiss machining is ideal for medium to large production runs. It supports:

-

Lights-out manufacturing

-

Reduced operator labor

-

Faster cycle times

-

Lower cost per part

5. Broad Material Compatibility

Swiss machining works with a wide range of materials including:

-

Stainless steel

-

Titanium

-

Aluminum

-

Brass

-

Copper

-

High-performance plastics (PEEK, PTFE, Delrin, etc.)

6. Cost-Effective for Complex, Small, or Long Parts

Although Swiss machines are more complex than conventional lathes, they significantly reduce secondary operations, tool changes, and scrap—leading to lower overall production costs.

Applications of CNC Swiss Precision Machining

Swiss turning is widely used in industries requiring miniature, intricate, and high-precision components:

Medical

-

Surgical instruments

-

Bone screws

-

Orthopedic implants

-

Dental components

-

Surgical robotics parts

Aerospace & Defense

-

Micro-fasteners

-

High-precision pins

-

Connectors and housings

-

Small bushings

-

Lightweight structural parts

Electronics

-

Micro-terminal pins

-

Sensor housings

-

RF and microwave connectors

-

Precision shafts and rods

Automotive

-

Fuel system components

-

Transmission micro-parts

-

Precision fasteners

-

Sensor components

Industries that rely on performance, safety, and reliability consistently prefer Swiss machining for their most demanding parts.

Challenges and Considerations

While CNC Swiss machining offers unmatched precision, it also comes with several considerations:

-

Size limitations: Most Swiss machines are ideal for small-diameter components.

-

Longer setup time: Complex programming and tooling require experienced operators.

-

Higher tooling cost: Live tooling and precision cutters increase initial expense.

-

Thermal management: Swiss machining requires excellent coolant control to maintain stability.

Xstar’s engineering team is trained to address these challenges through optimized tool paths, process control, and precision fixturing.

Future Trends in Swiss Precision Machining

The future of CNC Swiss machining is being shaped by advancements in automation, software intelligence, and sustainability:

-

AI-driven optimization for tool wear prediction and parameter adjustment

-

Digital twin simulation to validate tool paths before production

-

Fully automated robotic loading and unloading systems

-

Energy-efficient machining strategies to reduce waste

-

Hybrid subtractive + additive processes emerging for specialized components

Xstar is actively integrating these technologies to stay ahead of global manufacturing demands.

Why Choose Xstar for CNC Swiss Precision Machining

Xstar is committed to providing world-class precision machining solutions supported by:

✔ State-of-the-art Swiss CNC centers (multi-axis, live tooling, guide-bushing systems)

✔ Advanced bar-feeding automation for high-volume production

✔ Skilled engineering team specialized in micro-machining

✔ Tight tolerance control with CMM, optical inspection, and in-process measurement

✔ Full production scalability — from prototypes to mass production

✔ Experience across medical, aerospace, automotive, robotics, and electronics sectors

We combine engineering expertise with rigorous quality assurance to deliver consistent, repeatable, and highly accurate parts for critical applications.

Conclusion

CNC Swiss precision machining has become the preferred manufacturing method for ultra-tight-tolerance, small-diameter, and complex components. With superior accuracy, excellent repeatability, and high-volume efficiency, Swiss turning is essential for industries where precision can’t be compromised.

With advanced equipment, a skilled engineering team, and deep industry experience, Xstar stands as a trusted partner for companies seeking world-class precision machining solutions.

Call to Action

Looking for high-precision Swiss machining services?

Contact Xstar today for a free consultation or fast CNC machining quote.

Our experts are ready to support your next project—from prototype validation to full-scale production.