Prototype CNC Machining Explained: Processes, Industries, and Full Advantages Guide

Comprehensive Guide to Prototype CNC Machining for Modern Industry

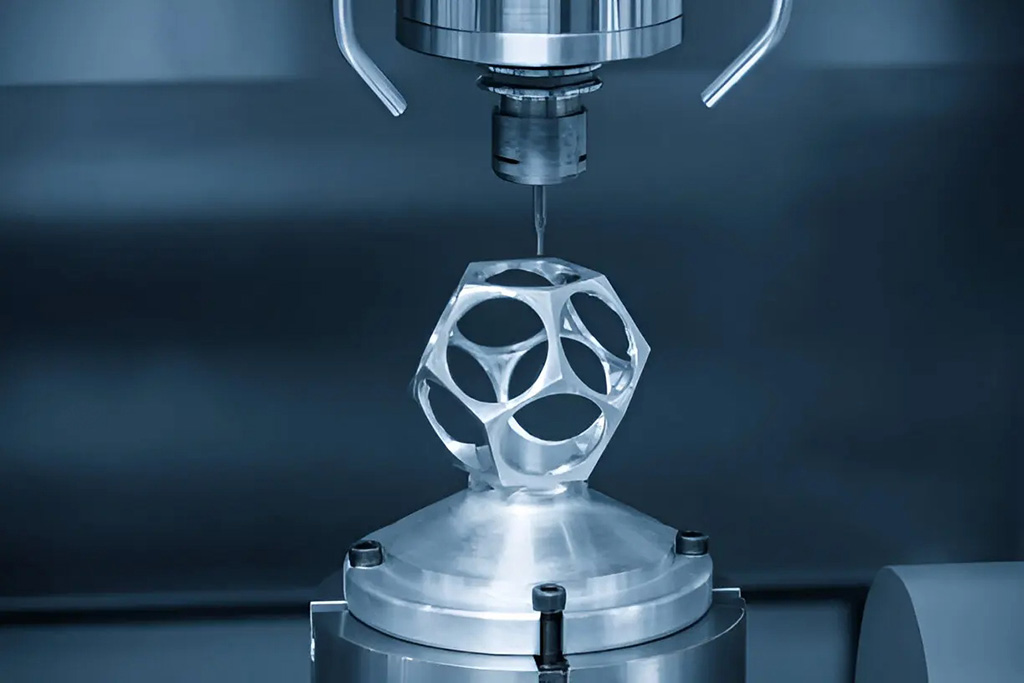

Prototype CNC machining has become one of the most relied-upon rapid manufacturing methods across aviation, medical devices, automotive engineering, and military defense sectors. When companies need functional prototypes that accurately represent final production parts, prototype CNC machining delivers unmatched precision, repeatability, and material versatility.

This article explores how prototype CNC machining works, why it is crucial for early-stage product development, how it compares with other rapid prototyping methods, and how specialized providers—such as prototype cnc machining services, prototype cnc milling, rapid prototype cnc machining, and cnc machining prototype service manufacturers—support global industries. We also address common questions such as what is cnc machining and how does it work and what is cnc technology to give a complete understanding of the manufacturing process.

1. What Is Prototype CNC Machining and Why It Matters?

Prototype CNC machining is the process of using computer-controlled milling, turning, drilling, and cutting equipment to create early-stage physical models from solid blocks of metal or plastic. Every toolpath is driven by CAD/CAM software, ensuring that the prototype accurately reflects the intended design.

What Is CNC Technology?

To understand prototype CNC machining, it is important to know what is cnc technology: it refers to computer numerical control systems that automate machine tools through programmed commands, enabling high repeatability and precision impossible with manual machining.

What Is CNC Machining and How Does It Work?

When customers ask what is cnc machining and how does it work, the answer is straightforward:

-

A CAD model is created.

-

CAM software generates toolpaths.

-

CNC machines execute the programmed motion.

-

Material is precisely carved away to reveal the desired shape.

Because no tooling molds are required, prototype CNC machining allows rapid iteration and low-volume production without the high cost of mold fabrication.

2. Industries That Rely on Prototype CNC Machining

Prototype CNC machining has gained widespread adoption because it supports nearly all engineering-grade materials, including aluminum, stainless steel, brass, titanium, magnesium, carbon steel, engineering plastics (ABS, PEEK, nylon), and composites.

Aerospace Components

Aviation engineers use prototype CNC machining for:

-

Turbine housings

-

Brackets and structural supports

-

Engine test components

-

Airflow testing models

Using prototype cnc milling, aircraft designers can refine aerodynamics, validate structural behavior, and ensure that parts meet strict tolerances. Materials like titanium and high-temp alloys are commonly used.

Medical Device Prototyping

Medical industries rely heavily on rapid prototype cnc machining to develop:

-

Surgical tools

-

Orthopedic implants

-

Dental components

-

Diagnostic equipment housings

Because CNC machining supports biocompatible materials and extremely tight tolerances, medical prototypes can be tested in real clinical environments.

Automotive Parts

Automakers utilize prototype CNC machining for components such as:

-

Engine housings

-

Gearbox prototypes

-

Brackets, mounts, and custom fittings

-

EV battery casings

CNC metal machining allows quick adjustments during vehicle development cycles, reducing time-to-market and enhancing performance testing.

Military & Defense Engineering

Defense contractors and prototype development specialists & cnc machining inc apply prototype CNC machining to:

-

Firearm components

-

Radar housings

-

Communication equipment

-

Precision optical and sensor mounts

Defense parts often demand high-strength metals like alloy steel and titanium, making CNC machining the preferred method due to reliability and consistency.

3. Core Processes in Prototype CNC Machining

Several machining processes are used in prototype development:

Prototype CNC Milling

A subtractive process where rotating tools remove material from metal or plastic blocks. Prototype cnc milling is ideal for:

-

Flat surfaces

-

Complex contours

-

Pockets and cavities

-

High-precision features

-

Multi-face machining using 3-, 4-, or 5-axis milling

Turning and Lathe Machining

Used for cylindrical parts such as shafts, bushings, spacers, and threaded components.

Drilling, Boring, and Tapping

Essential for functional prototypes requiring:

-

Threaded holes

-

Accurate pilot holes

-

Precision bores for mechanical assembly

Surface Finishing

Prototypes can be finished with:

-

Bead blasting

-

Anodizing

-

Powder coating

-

Polishing

-

Black oxide

-

Brushed finishes

These processes ensure prototypes accurately reflect the final design intent.

4. Advantages of Prototype CNC Machining

Prototype CNC machining is selected for many reasons:

1. Material Flexibility

Unlike 3D printing, CNC machining supports production-grade metals and plastics. This makes prototypes functional for real-world mechanical testing.

2. High Precision

CNC machines deliver tolerances as tight as ±0.005 mm, suitable for aerospace and medical components.

3. Fast Turnaround

With no mold tooling required, prototypes can be delivered in 2–7 days, a major advantage for product development cycles.

4. Excellent Surface Quality

CNC-machined prototypes have superior surface quality compared to additive manufacturing methods.

5. Repeatability

The same CAD/CAM program ensures consistent quality for multiple prototype iterations.

5. Limitations of Prototype CNC Machining

Although highly beneficial, prototype CNC machining has several limitations:

1. More Expensive for Very Complex Shapes

Intricate shapes involving deep internal channels may require multi-axis machining, increasing cost compared to certain 3D printing methods.

2. Material Waste

As a subtractive process, CNC machining generates more material waste than additive manufacturing.

3. Some Geometries Are Not Feasible

Internal cavities that cannot be reached by toolpaths will require redesign or a hybrid manufacturing approach.

4. Longer Setup for Multi-Part Projects

Complex prototypes with many components require more CAM programming time.

Despite these limitations, most cnc machining prototype service manufacturers still rely on CNC machining as the most stable and accurate method for functional prototypes.

6. Choosing the Right Prototype CNC Machining Partner

When evaluating prototype cnc machining services, buyers should consider:

-

Capability in multi-axis machining

-

Experience in aerospace, medical, automotive, or defense fields

-

Range of supported materials

-

Inspection systems (CMM, quality control)

-

Turnaround speed

-

Pricing

-

Scalability from prototype to mass production

Companies like prototype development specialists & cnc machining inc provide end-to-end support, from early prototype engineering to final production consulting, offering both rapid prototype cnc machining and long-term manufacturing solutions.

We are a manufacturing-and-trading integrated supplier specializing in prototype cnc machining services, focusing on CNC subcontracting and precision machining for a broad range of metal components. Our production capabilities include CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloys, CNC machining acrylic, CNC machining ABS, and CNC machining various plastic materials.

We also provide high-precision machining solutions for multiple industries such as robotics component machining, aerospace parts machining, marine component machining, automotive parts machining, and medical device machining, covering most CNC precision processing needs across industrial applications.

Our CNC machining services offer excellent dimensional accuracy, rapid production speed, stable and consistent performance, and broad material compatibility. A wide selection of finishing processes is available, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk-screen printing, and textured surface treatment.

As a dedicated CNC machining service manufacturer, we support both prototype machining and mass production. If you would like to check the cnc turnning price of our prototype cnc machining services, feel free to contact us at any time.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.