Mastering Precision Manufacturing with 5 Axis CNC Machining Services

In today’s global manufacturing landscape, 5 axis CNC machining services have become the benchmark for producing highly complex, ultra-precise components across aerospace, automotive, medical devices, robotics, electronics, and industrial equipment. With their ability to simultaneously move a cutting tool or part along five different axes, these services dramatically improve efficiency, reduce manual setups, and achieve geometries that traditional machining cannot reach. For businesses seeking tighter tolerances, smoother finishes, and faster turnaround times, investing in or outsourcing 5 axis CNC machining services is no longer optional—it’s a strategic advantage.

Whether you are developing prototypes or scaling large-volume production, understanding the capabilities and value of these services is essential. This comprehensive guide explores every dimension—from how the technology works to where to find trusted providers.

What Is a 5-Axis CNC Machine?

Understanding what is a 5-axis CNC machine is the first step in appreciating its unparalleled capabilities. A 5-axis CNC machine moves a part or tool along the X, Y, and Z axes while simultaneously rotating on the A and B axes. This combination allows machining from multiple angles in a single setup, eliminating the need for manual repositioning and significantly improving precision.

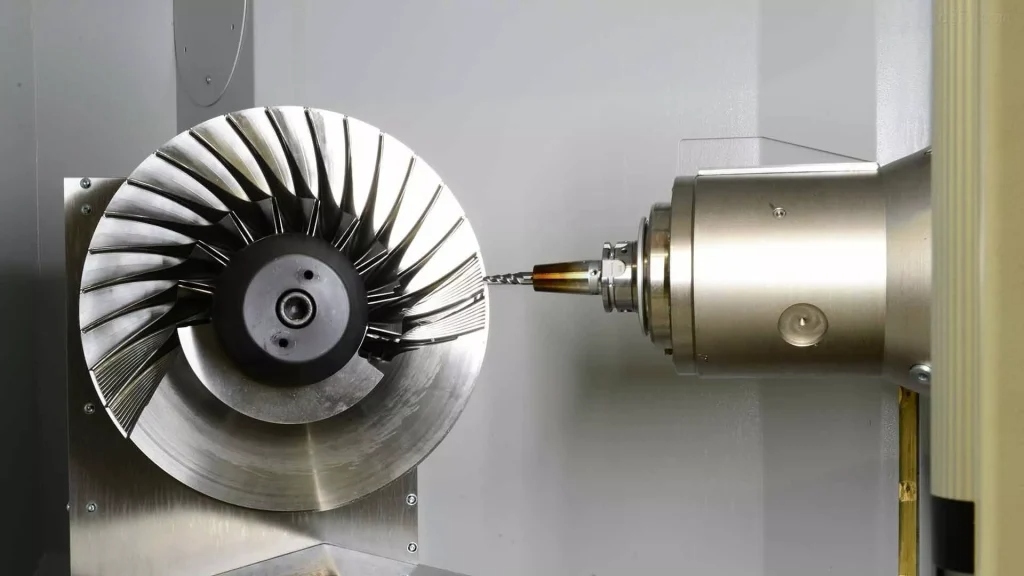

Manufacturers rely on 5-axis systems to produce components with undercuts, deep cavities, compound angles, and complex surface contours. Industries requiring medical implants, turbine blades, injection-mold inserts, and aerospace structural parts are heavily dependent on the precision of what is a 5-axis CNC machine because of its ability to deliver consistent quality for even the most demanding geometries.

What Can a 5 Axis CNC Machine Do?

When discussing what can a 5 axis CNC machine do, the answer spans from extremely delicate micro-machining to large structural part fabrication. These machines can:

-

Mill multi-surface features in one pass

-

Manufacture impellers, manifolds, gears, and aerospace brackets

-

Achieve tolerances up to ±0.002 mm

-

Reduce human error by eliminating frequent part repositioning

-

Improve surface quality through continuous tool engagement

This capability allows manufacturers to meet high-complexity requirements while reducing cost and production time. When you fully grasp what can a 5 axis cnc machine do, you begin to understand why this technology leads modern precision manufacturing.

Benefits of Choosing Professional 5 Axis CNC Machining Services

Businesses increasingly turn to professional 5 axis CNC machining services because of their ability to support complicated design requirements. The benefits include:

1. Ultra-High Precision

5-axis machines maintain consistent tool orientation and optimal cutting angles, ensuring superior accuracy.

2. Shorter Lead Times

With fewer setups required, machining time and inspection cycles are minimized.

3. Superior Surface Finish

Constant tool engagement reduces tool marks and improves overall part aesthetics.

4. Cost Efficiency

Although 5-axis machining may seem more expensive initially, reduced rework and faster production make it highly cost-effective.

Whether you are in aerospace, medical technology, or automotive manufacturing, the versatility of 5 axis CNC machining services enables you to confidently produce components that traditional machining cannot achieve.

5 Axis CNC Machining Services Near Me — How to Choose a Local Provider

A growing number of customers search for 5 axis CNC machining services near me to find convenient, fast, and cost-effective production. When selecting a local provider, consider the following:

-

Machine capabilities (travel size, spindle power, cutting speed)

-

Supported materials (aluminum, stainless steel, titanium, copper, ABS, PEEK, nylon, composites, PC)

-

Inspection equipment (CMM, laser scanners, in-process probing)

-

Experience in your industry

-

Sample quality and previous projects

Using a trusted provider offering 5 axis CNC machining services near me allows for easier communication, faster delivery, onsite visits, and smoother project management.

5 Axis CNC Milling Service — Precision for Complex Geometries

A dedicated 5 axis CNC milling service focuses on milling-based manufacturing, ideal for creating deep pocketing, angled walls, contoured surfaces, and multiple side features. Compared to 3-axis or 4-axis milling, a 5 axis CNC milling service can:

-

Access five sides of a part in one fixture

-

Maintain the shortest tool length to reduce vibration

-

Improve machining stability and accuracy

-

Produce complex tooling used for injection molds, jigs, and aerospace structures

Whether you need small-batch prototypes or high-volume production, a specialized 5 axis CNC milling service delivers unmatched versatility and dimensional stability.

Role of 5 Axis CNC Machine Companies in Modern Manufacturing

Across the world, numerous 5 axis CNC machine companies support industrial growth by manufacturing advanced machines, developing high-performance control software, and providing customer support and training. These companies supply 5-axis technology to aerospace corporations, automotive factories, medical labs, and precision machining shops.

When choosing among 5 axis CNC machine companies, buyers typically evaluate:

-

Machine rigidity and accuracy

-

Control system ease-of-use

-

Availability of automation and robotic loading

-

After-sales support and global service coverage

Reliable 5 axis CNC machine companies help industrial manufacturers remain competitive by offering state-of-the-art machining solutions.

Materials Commonly Used in 5 Axis CNC Machining Services

High-end 5 axis CNC machining services can process an extensive range of metals and engineering plastics, including:

Metals

-

Aluminum 6061, 7075, 2024

-

Stainless Steel 304, 316, 17-4PH

-

Titanium Grade 5

-

Brass & Copper

-

Magnesium Alloys

Plastics & Composites

-

ABS, POM, Nylon, PC, PMMA

-

Carbon Fiber Reinforced Polymers (CFRP)

-

Glass Fiber Composites

The adaptability of 5 axis CNC machining services ensures precise results even with materials that are brittle, high-strength, or difficult to machine.

Industries That Benefit from 5 Axis CNC Machining Services

These industries rely heavily on advanced 5-axis technology:

-

Aerospace (turbine blades, structural supports, housings)

-

Automotive (engine housings, gearbox components)

-

Medical (prosthetics, surgical tools)

-

Robotics (frames, joints, precision connectors)

-

Electronics (heat sinks, enclosures)

-

Mold Manufacturing (cavities, complex cores)

The wide applicability of 5 axis CNC machining services continues to transform how modern products are designed and manufactured.

We are a manufacturing-and-trading integrated company specializing in professional 5 axis cnc machining services, mainly engaged in CNC subcontracting and precision machining of various metal components. Our machining capabilities cover CNC machining aluminum profiles, CNC machining stainless steel, CNC machining magnesium alloys, CNC machining acrylic, CNC machining ABS, and CNC machining various plastic materials.

We also support high-precision part machining for multiple industries, including robotics component machining, aerospace parts machining, marine component machining, automotive parts machining, and medical device machining, meeting the CNC precision requirements of most industrial fields.

Our CNC machining services deliver high accuracy, fast production efficiency, stable quality, and excellent compatibility with different materials. Available surface finishing options include sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum coating, chemical plating, phosphating, passivation, silk-screen printing, and textured finishing.

As a dedicated 5 axis cnc machining manufacturer of 5 axis cnc machining services, we support both prototype machining and mass-production machining. If you would like to know the 5 axis cnc machining price of our 5 axis cnc machining services, feel free to contact us anytime.

Some content in this article is sourced from the internet. If there is any inappropriate content, please contact us for removal.