CNC Precision Machining Services by XSTAR – High-Accuracy Parts Manufacturer

Why CNC Precision Machining Matters for High-Quality Parts

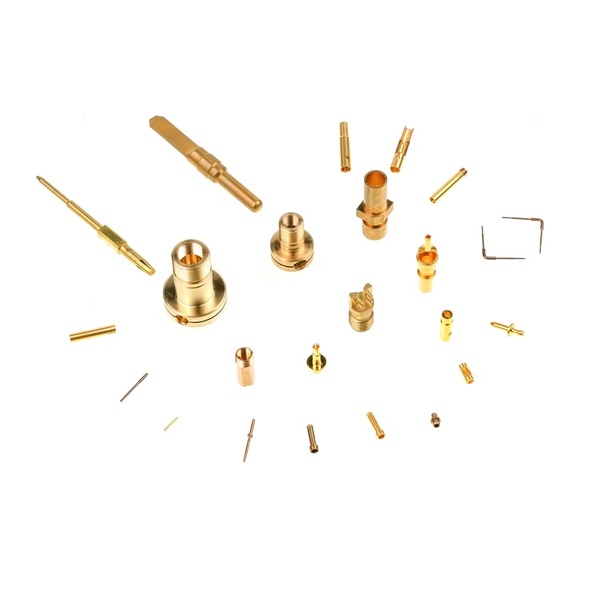

In modern manufacturing, CNC precision machining has become one of the most trusted and efficient ways to produce highly accurate, repeatable, and complex parts. Whether for aerospace, robotics, medical, automotive, or industrial applications, the demand for tight tolerances and high-quality finishes makes precision CNC machining indispensable.

What Is CNC Precision Machining?

CNC precision machining is a computer-controlled subtractive manufacturing process. Using CAD/CAM data, CNC machines (mills, lathes, grinders) remove material from a raw workpiece under precise control. This allows manufacturers to produce parts that match detailed specifications and tight tolerances.

Unlike more general CNC work, precision machining focuses on parts with very small tolerances, complex geometries, and high consistency. Because of this control, precision CNC machining is widely used in high-tech fields such as aerospace, medical, and electronics.

Before we begin, if you need a CNC machining service quote, please contact us for a free estimate.

Key Advantages of CNC Precision Machining

High Accuracy & Tight Tolerance

One of the biggest strengths of CNC precision machining is its exceptional accuracy. Tight tolerances (in the order of microns) are routinely achievable, which is essential for parts that must fit and function reliably in assemblies.

Excellent Repeatability

Because the machinery is computer-controlled, once a program is dialed in, the same machining steps can be reproduced with very little variation. This means large batches can be produced consistently, which is key for quality control.

Material Versatility

Precision CNC machining supports a wide variety of materials, from soft plastics to high-strength metals. This makes it a flexible option for diverse industries.

Efficient Production & Automation

Once set up, CNC machines can run with minimal supervision, lowering labor costs and boosting productivity. Also, complexity doesn’t necessarily mean more work: multifunction machines can combine operations like milling, turning, and grinding in a single workflow.

Cost-Effective in the Long Run

Although precision CNC machining can require substantial initial investment, over time it becomes very cost-effective thanks to reduced waste, lower labor needs, and repeatability.

Challenges & Limitations

-

Programming & Setup: Precision CNC machining requires skilled CAM programmers and proper tool presetting before production begins.

-

High Equipment Costs: High-precision machines (mills, grinders, Swiss lathes) and their maintenance can be costly.

-

Material Waste: Because the process is subtractive, some material is removed and not reused — though good planning minimizes this.

-

Accessibility: Very tight tolerance programs need careful validation to avoid collisions or production errors.

Precision CNC Machining Processes & Equipment

To achieve high-precision results, several specialized processes and machines are often used:

-

CNC Milling & Turning: Machining centers cut and shape parts, sometimes combining operations in a mill-turn machine.

-

Precision Grinding: After rough cutting, parts may be ground with abrasive wheels to achieve very flat surfaces or fine finishes.

-

Multi-Axis Machining: Using 4- or 5-axis machines, complex geometries can be machined in fewer setups.

-

Swiss-Style Turning: For very small or slender parts, Swiss lathes offer excellent stability and precision.

Tolerances & Design Considerations

In precision CNC machining, tolerance is critical. Designers must decide how tight tolerances need to be: sometimes not every dimension needs ultra-high precision. Choosing appropriate tolerances can help reduce cost and simplify manufacturing.

For example, very tight tolerance demands might require more expensive machines or slower cutting speeds.

Where Precision CNC Machining Is Commonly Used

Here are a few typical application areas for precision CNC machining:

-

Aerospace: Structural components, brackets, and housings that demand tight tolerances and high performance.

-

Medical Devices: Implants, surgical instruments, and diagnostic tools that require micron-level precision.

-

Automotive: Prototypes, precision fittings, and high-performance parts.

-

Electronics: Housings and mechanical parts for precision instruments.

Global & Local Precision CNC Machining

-

CNC Precision Machining China: Many factories in China specialize in high-precision CNC machining, offering competitive pricing and strong manufacturing capacity. Thanks to economies of scale and advanced equipment, precision machining in China is a top choice for many international buyers.

-

CNC Precision Machining Factory: A full-service factory with precision CNC machines (milling, turning, grinding) can handle from prototyping to volume production.

-

CNC Precision Machining Services: These refer to the broader service offerings—design review, material sourcing, machining, finishing, and quality inspection.

-

CNC Precision Machining Near Me: For customers who prefer local suppliers, local precision CNC shops offer short lead times and face-to-face communication, though sometimes at a higher unit cost due to labor.

-

CNC Precision Machining Pty Ltd: In some regions (e.g., Australia), a company with the name “Pty Ltd” may provide precision CNC machining services, serving local industries with high-quality, reliable machining.

Why XSTAR Excels in CNC Precision Machining

At XSTAR, we combine decades of machining experience with a modern, factory-integrated structure to deliver top-tier CNC precision machining services. Here’s why customers trust us:

-

Wide Material Compatibility: We machine aluminum, stainless steel, magnesium, ABS, acrylic, and more.

-

Advanced Capabilities: Our equipment includes mills, turning centers, grinders, multi-axis machines, and more, all optimized for precision work.

-

High-Accuracy Tolerances: We consistently meet tight tolerances and deliver repeatable quality, thanks to digital controls, inspections, and well-calibrated toolpaths.

-

Comprehensive Post-Processing: After machining, we offer surface treatments like polishing, anodizing, plating, passivation, sandblasting, and more to enhance part performance and aesthetics.

-

Efficiency & Speed: Our workflow—from CAD/CAM programming to final inspection—is designed for fast prototyping and efficient production.

-

Quality Assurance: We thoroughly inspect each batch to ensure dimensional accuracy, surface quality, and consistency.

-

Customer-First Approach: We serve global and local clients, whether they need “precision CNC machining near me” or want to work with a reliable “precision CNC machining factory.”

If you need precision parts made with high quality, fast turnaround, and stable performance, XSTAR is your ideal partner. Please contact us with your drawings and specifications — we’ll provide a competitive quote and handle your custom CNC precision machining project.

We are an integrated trading and manufacturing company specializing in CNC machining services, mainly focused on CNC subcontracting and the precision CNC machining of various metal components. Our machining capabilities include CNC machining of aluminum profiles, CNC machining of stainless steel, CNC machining of magnesium alloys, CNC machining of acrylic, CNC machining of ABS, and CNC machining of multiple plastic materials. We provide CNC precision machining services for a wide range of industries, including robotics machining, aerospace component machining, marine component machining, automotive parts machining, medical devices, industrial machinery, and many other sectors requiring high-accuracy CNC components.

Our CNC machining services deliver high precision, fast efficiency, stable quality, and strong compatibility. We support a comprehensive selection of surface finishing processes, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, electroless plating, phosphating, passivation, silkscreen printing, and texture finishing.

As a professional CNC machining service manufacturer, we provide batch CNC machining services. For inquiries about CNC machining service pricing, feel free to contact us. We also offer internal linking support for cnc precision machining, cnc precision machining manufacturer, and cnc precision machining price to enhance navigation across related product pages on our website.

Portions of this article are sourced from the internet. Should any inaccuracies be found, please contact us for resolution.