Why CNC Milling Machining Matters for Precision Parts

In modern manufacturing, CNC milling machining plays a vital role. CNC (Computer Numerical Control) milling offers high precision, repeatability, and flexibility in creating complex parts. For industries like robotics, aerospace, marine, automotive, medical, and industrial equipment, CNC milling machining is often the go-to choice for prototyping and production.

What Is CNC Milling Machining?

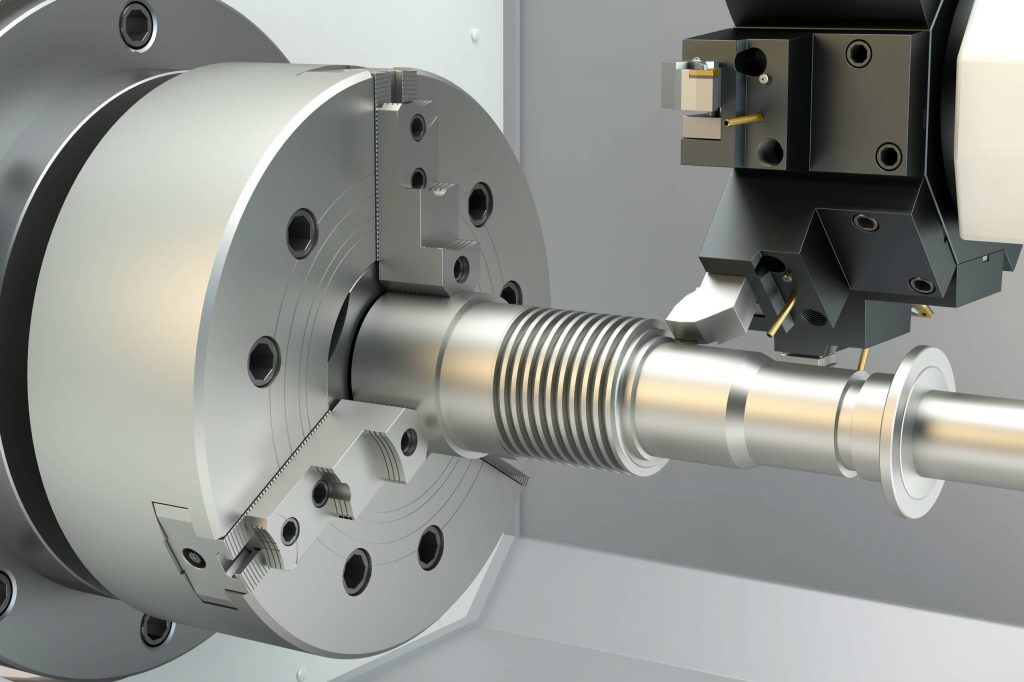

CNC milling machining is a subtractive process where rotating cutting tools remove material from a workpiece under computer control. Starting from a CAD model, the design is translated into machine-readable G-code, and the CNC mill executes precise toolpaths to shape components. Unlike simple drilling or turning, a milling center can move the tool along multiple axes to cut complex geometries.

A CNC milling machining center typically has an automatic tool changer with a magazine that holds many tools. This lets the machine switch tools during the same job, enabling complex sequences without manual intervention.

Key Advantages of CNC Milling Machining

-

High Precision & Consistency

CNC milling can achieve very tight tolerances because the machine follows digital instructions.Human error is largely eliminated, so parts are consistent even in large volumes. -

Efficiency & Speed

Because of automation, CNC milling machines can run continuously, dramatically reducing the time per part. Automatic tool changes and optimized cutting paths improve throughput. -

Design Flexibility

The multi-axis capability of CNC milling allows for very complex designs, such as pockets, slots, chamfers, and contours. -

Wide Material Compatibility

CNC milling supports a variety of materials—metals (aluminum, stainless steel, magnesium), plastics (ABS, acrylic), composites, and more. -

Repeatability & Automation

Once the milling program is set up, the machine produces identical parts with minimal human supervision. -

Digital Simulation & Optimization

Before actual machining, the G code CNC machining milling simulator can model toolpaths and optimize for time, reducing risk and improving quality. -

Cost-Effectiveness

Although initial investments in CNC milling centers are high, the long-term benefits—such as reduced labor costs, fewer errors, and material savings—make it cost-effective. -

Safety

Automation reduces operator exposure to cutting tools. Emergency stops and enclosed machines make CNC milling safer.

Challenges & Considerations

-

Material Wastage

Since CNC milling is subtractive, there can be more waste compared to additive methods like 3D printing. -

High Equipment Cost & Maintenance

CNC milling machines, especially multi-axis centers, can be expensive to purchase and maintain. -

Skilled Programming Required

You need trained operators who can write G-code, calculate optimal feed rates, and handle setup.

Exploring the CNC Milling Machining Process

The CNC milling machining process typically involves:

-

CAD Design: Create a 3D model of the part.

-

CAM Programming: Translate the design into G-code and M-code.

-

Machine Setup: Fix the workpiece, load tools, set tool offsets.

-

Machining: The mill follows the toolpath to cut the material.

-

Inspection & Post-Processing: After milling, parts may undergo finishing (grinding, polishing, heat treatment, etc.).

Calculating CNC Milling Machining Time

Estimating CNC milling machining time is critical for planning and cost control. Time depends on several factors:

-

Toolpath complexity (how many axes, how many operations)

-

Material type (harder materials cut more slowly)

-

Spindle speed & feed rate

-

Depth of cut & width of cut

-

Number of tool changes

Simulators and CAM software help predict machining time by modeling these parameters and interpolating the feed rate along the tool path.

CNC Milling vs Other Processes

-

CNC Machining Milling and Turning: Some parts require both milling and turning. Turning is good for round workpieces, while milling excels at flat, complex, or prismatic geometries. Hybrid machines can perform both.

-

CNC Machining vs Milling: “Machining” is a broader term covering milling, turning, drilling, etc. Milling specifically refers to cutting with a rotating tool.

-

G Code CNC Machining Milling Simulator: This tool helps verify and optimize the G-code before actual machining, reducing risk and ensuring efficiency.

Applications & Use Cases

-

Aerospace & Aviation: High-precision structural parts, brackets, and housings.

-

Automotive: Prototype parts, molds, transmission components.

-

Robotics & Automation: Custom bars, mounts, and assemblies.

-

Medical Devices: Implants, surgical tools, custom fixtures.

-

Industrial Equipment: Machine frames, tool components, jigs.

Why Choose XSTAR for CNC Milling Machining

At XSTAR, we provide world-class CNC milling machining services with full factory integration. As a CNC milling machining service provider and manufacturer, we bring deep expertise in:

-

Milling all kinds of metals (aluminum, stainless steel, magnesium) and plastics (ABS, acrylic)

-

Using advanced CNC milling centers (3-axis, 4-axis, 5-axis) for complex shapes

-

Offering post-processing: surface finishing, polishing, anodizing, coating, and more

-

Ensuring tight tolerances, stable quality, fast turnaround, and high efficiency

Whether you need one prototype or a batch of production parts, XSTAR is ready to deliver. Contact us now to discuss your CNC milling machining needs and get a quote.

We are an integrated trading and manufacturing company specializing in CNC machining services, mainly focused on CNC subcontracting and precision CNC machining of various metal parts. Our capabilities include CNC machining of aluminum profiles, CNC machining of stainless steel, CNC machining of magnesium alloys, CNC machining of acrylic, CNC machining of ABS, and CNC machining of multiple plastic materials. We provide high-precision CNC machining for a wide range of industries, including robotics machining, aerospace component machining, marine component machining, automotive parts machining, medical equipment, industrial machinery, and many other sectors requiring precision-engineered CNC parts.

Our CNC machining services offer high accuracy, fast efficiency, stable quality, and strong compatibility. We support a broad selection of surface finishing processes, including sandblasting, hard anodizing, micro-arc oxidation, grinding, polishing, painting, blackening, electroplating, vacuum plating, electroless plating, phosphating, passivation, silkscreen printing, and texture finishing.

As a professional CNC machining service manufacturer, we provide batch CNC machining services. For inquiries about CNC machining service pricing, feel free to contact us. We also provide internal link support for cnc milling machining, cnc milling machining manufacturer, and cnc milling machining price to enhance navigation across related product pages on the website.

Some content in this article is sourced from the internet. Should any inaccuracies arise, please contact us for resolution.